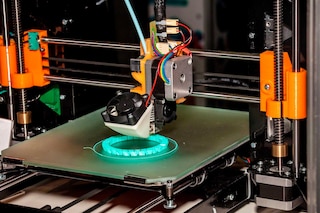

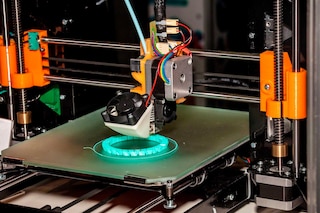

3D printing takes supply chain management into a new dimension

January 4, 20213D printing constitutes technology with an enormous potential for transforming logistics and transportation. Its main characteristic is easy product personalization.

Explore the Interlake Mecalux blog and learn more about the latest methods for warehouse space optimization, how to improve inventory management, automated material handling equipment & software.

3D printing constitutes technology with an enormous potential for transforming logistics and transportation. Its main characteristic is easy product personalization.

Inventory management with Excel: nowadays, many businesses depend on this to control their warehouse stock. But is it enough? WMSs ensure comprehensive goods control in real time.

Minimizing and managing backorders means that a company’s supply chain is efficient and that its warehouse is free of stockouts.

Warehouse manager is a position of great responsibility in any company, regardless of sector, as this key figure’s role is to manage all processes taking place in the warehouse.

The demand for warehouses closer to cities — which breaks with the tradition of setting up logistics centers far from large urban areas — has led to a shortage of available land.

A detailed bill of materials increases the throughput of all supply chain processes. There are various types of BOMs, depending on activity and business needs.

Kitting is a process aimed at boosting assembly line productivity. It consists of compiling the materials and components necessary to manufacture a product.

Dark warehouses are installations in which no lighting is required: all processes taking place in them are fully automated, doing away with the need for human intervention.