Warehouse Organization & Design

Searching for the tools and ideas to design an expert warehouse floor plan? Discover how to maximize space and productivity with the latest technology in racking and automated systems.

-

-

Pareto chart: How to make one and examples in logistics

-

What is CMMS software?

-

Automotive logistics: Key challenges and how to tackle them

-

Dead stock and how to avoid it

-

Waybill for goods transportation

-

Supply chain strategies for business success

-

Inventory turnover: The key to warehouse efficiency

-

Cartonization and its benefits for logistics

-

Electric vehicles in logistics and freight transportation

-

Warehouse setup: definition, types, and examples

-

FEFO: optimizing inventory management for perishable goods

-

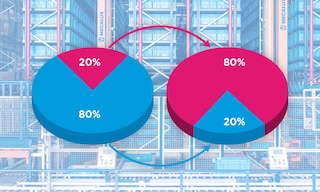

Pareto law: optimizing logistics processes with the 80/20 rule

-

Logistics history: origin and development

-

Warehouse areas: essential zones for efficient management

-

Double handling: example of waste in Lean logistics

-

Hoist: definition and function in warehousing

-

Logistics processes: key points for optimizing your supply chain

-

Freight deconsolidation: a key inbound operation

-

FIFO method in inventory management