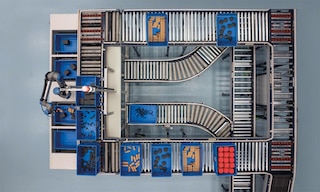

Warehouse Automation

Learn about automated material handling & how to reduce costs with safe product management and delivery. Discover the benefits of stacker cranes, conveyor systems, pallet shuttles & mobile racks.

-

-

Micro warehousing: The logistics response to ecommerce immediacy

-

Supply chain planning: How to optimize this critical process

-

Greenfield vs. brownfield logistics projects

-

Automated order picking and how it boosts order fulfillment

-

The 4 way shuttle for pallets

-

What is SCADA? The system behind smarter industrial and logistics processes

-

Heat treated pallet: Types of treatment and ISPM 15 compliance

-

Shunting in logistics: Streamlining yard operations

-

What is Industry 4.0?

-

Make to order (MTO): Benefits and challenges of manufacturing on demand

-

Advanced air mobility (AAM): A near-future reality?

-

LiDAR system and its main industrial applications

-

Slave pallet: Definition and main applications

-

Inductive charging and its advantages for industry

-

AMR warehouse: A new era in in-house transport

-

SLAM navigation and how it impacts robotics

-

Ruggedized explained: Tough tech for industrial environments

-

Industrial automation and its advantages in warehousing

-

Internal transport: systems and examples