Store Fulfillment

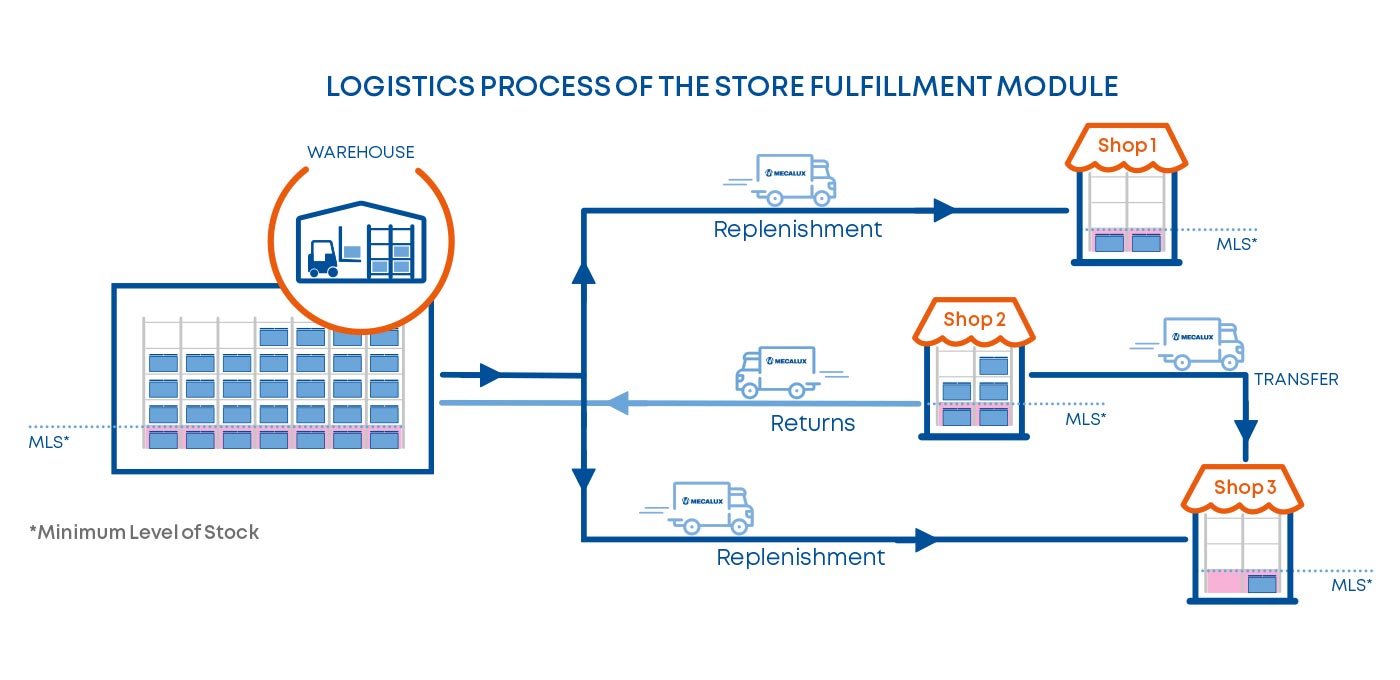

Store Fulfillment synchronizes inventory and workflows to ensure optimal stock management between the central warehouse and the physical store network

Ask our expertsEfficient stock management for distribution to physical shops

The Store Fulfillment module has been designed for companies that need real-time control over inventory of their warehouse and physical stores. Additionally, it syncs supply operations throughout the distribution network such as picking, replenishment, transfers between stores, and returns.

WHAT BENEFITS DOES STORE FULFILLMENT PROVIDE?

|

|---|

Store Fulfillment synchronizes inventory and workflows to ensure optimal stock management between the central warehouse and the physical store network

Best-in-class features of Store Fulfillment

- WMS integration with point of sale (POS) terminals

- Automatic replenishment of shop items depending on stock level

- Task generation after an in-shop sale or return

- Transfers of in-warehouse items to shops or between shops

- Warehouse management with cash-and-carry model

- Quick in-shop stock counts

- Automatic reports (stock level by shop or stock on the way, etc.)

Store Fulfillment adapts to different shop types

Central warehouse with management of independent stores

A distribution center serves one or more stores in different geographical locations. Stores are replenished with goods available in the distribution center. The system controls returns and transfers between stores.

Warehouse with direct sales

Customers pick the products they need from the shelves and pay at the counter. In this case, the store and warehouse inventory are managed separately.

Warehouse with management of integrated store

Customers order the products they need at the store counter. Then, operators are responsible for locating them in the warehouse. Once the sale is made, the system updates the inventory automatically.