Yard Management System (YMS)

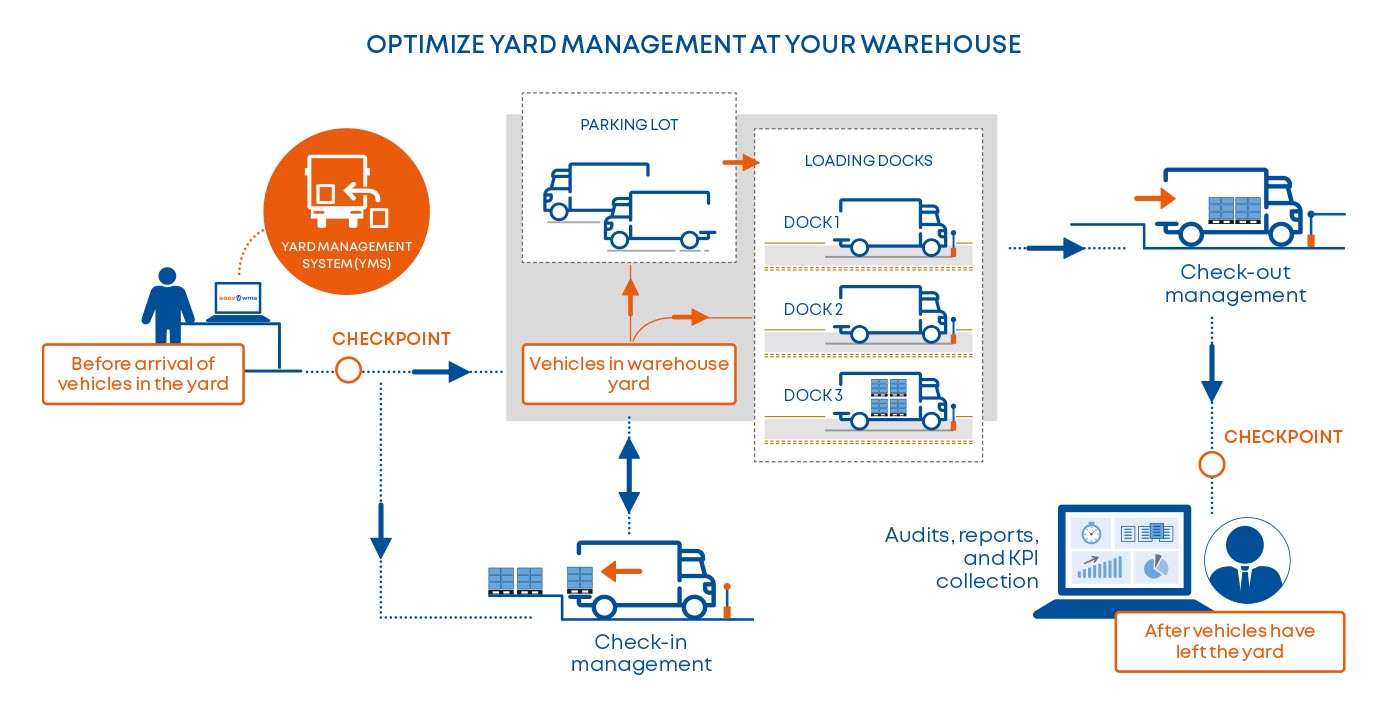

Yard Management System (YMS) module supervises movements of vehicles in the yard, at the docks, in the car park and at the warehouse access control points

Ask Our ExpertsEliminate bottlenecks at the docks

This advanced Easy WMS functionality supervises movements of vehicles in the yard, at the docks, in the parking lot, and at the warehouse access control points. The software provides logistics managers with real-time visibility of incoming and outgoing vehicles. It also displays KPIs and generates reports and audits to improve punctuality rates and warehouse efficiency.

Yard Management System (YMS) syncs operations at the loading docks, enabling efficient planning of goods receipt and dispatch. It monitors traffic in the yard, at the docks, and in the parking zones at all times, enabling fast reassignment of vehicles to docks if necessary.

Monitor vehicle movements in the warehouse yard and eliminates bottlenecks

BENEFITS OF YARD MANAGEMENT SYSTEM

|

|---|

Yard Management System ensures control over the management of warehouse yards

Functions of Yard Management System (YMS)

- Planning and management of appointments for goods delivery and/or pick-up

- Coordination of stock check-in and check-out

- Synchronization of loading and unloading areas, parking lots, and access points

- Notification to drivers of data such as available docks, outbound goods, etc.

- Audits, reports, and KPI collection

Synchronization of movements in the warehouse yard

To improve logistics service in warehouse yards, Yard Management System (YMS) enables effective communication between customers, logistics providers, and drivers: it automatically notifies drivers of the most relevant data, i.e., available docks and outbound goods.

The Easy WMS module validates the check-in of all vehicles that access the yard. After identifying them, it automatically assigns each vehicle a dock or parking space. In this stage, the module is responsible for managing all vehicles in the yard and supervising the status of the docks and of each parking space.

YMS also optimizes vehicle exits: it checks exit times to carry out audits, identifies goods and drivers, and prepares and prints the necessary documentation.