Kaizen: The art of changing for the better in business

The kaizen philosophy, first applied in the late 1940s, gained traction among Japanese manufacturing executives in the 1980s. Since then, it has become a key tool for companies seeking continuous process improvement and high efficiency levels.

What does kaizen mean?

The word kaizen comes from the Japanese terms kai (改), meaning change or revision, and zen (善), translated as virtue or goodness. In essence, it means “change for the better.” The kaizen method focuses on operational excellence and continuous improvement across all business areas by making incremental changes to the way work is done. Its goal is to help companies build organizational systems that support their long-term objectives. Closely tied to lean manufacturing, kaizen promotes an inclusive, participatory work environment where ideas help eliminate inefficiencies and boost productivity.

Origins of the kaizen method

Kaizen began to take shape in post-World War II Japan. With widespread shortages of food and energy and an industrial sector in crisis, the Japanese people quickly realized that if they wanted to rebuild, they couldn’t rely on their traditional production processes. The term kaizen is associated with the Japanese Union of Scientists and Engineers (JUSE) and was later popularized in the 1980s by management consultant Masaaki Imai, founder of the Kaizen Institute.

Despite its Japanese roots, American quality management experts such as W. Edwards Deming (known for the Deming cycle) and Joseph Duran also played an important role in developing the kaizen methodology. After the war, both visited Japan to share their insights on quality control and statistical management. Japanese companies then integrated these ideas into their work methods.

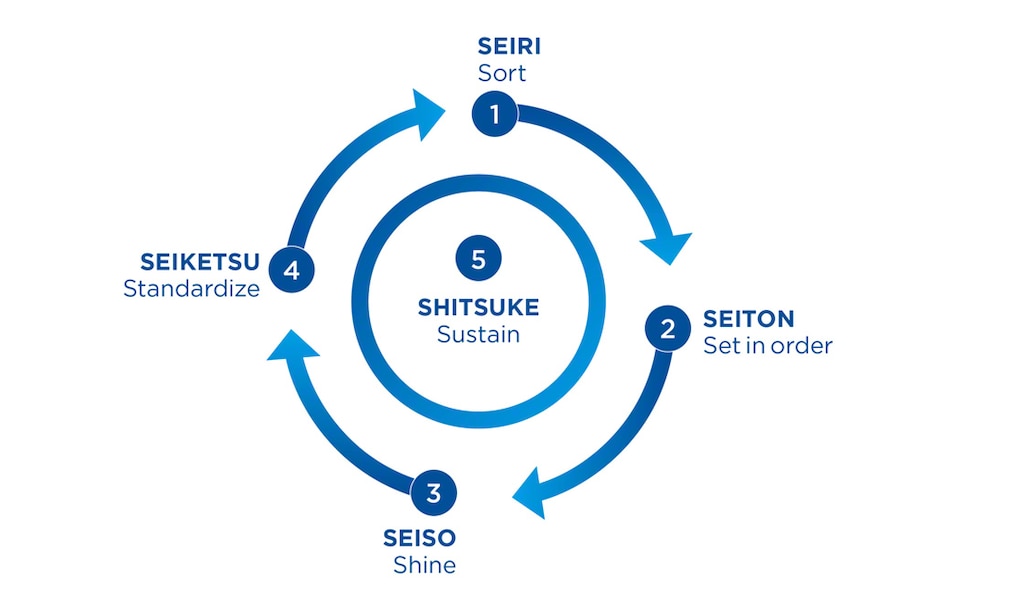

The 5S of kaizen

The kaizen concept is based on five Japanese words — Seiri, Seiton, Seiso, Seiketsu, and Shitsuke — known as the 5S:

- Sort (Seiri). The starting point is eliminating anything unnecessary or that adds no value. Besides freeing up space, this step removes elements that hinder organizational efficiency.

- Set in order (Seiton). Order is an asset for productivity. Keeping everything in its place ensures a smoother workflow and reduces time wasted looking for items.

- Shine (Seiso). Beyond making the workspace more pleasant, cleanliness improves safety. With less visual clutter, it’s easier to detect and address malfunctions or other incidents, supporting continuous improvement.

- Standardize (Seiketsu). This involves maintaining the first three steps (Seiri, Seiton, and Seiso) through standard procedures and visual controls that encourage best practices and help maintain order.

- Sustain (Shitsuke). All stakeholders must commit to embracing better ways of working and ensuring long-term transformation.

10 principles for improving processes with kaizen

While the 5S forms the foundation of kaizen, its philosophy and implementation can also be summed up in these 10 principles:

- Set aside assumptions and question current practices, always recognizing there’s room for improvement. Progress is continuous and never-ending.

- Solve problems proactively. Explore ways to make improvements instead of dismissing them, and look for ideas — even in difficult situations.

- Focus on the positive rather than the negative. Instead of stating how not to do a task, explain how it should be done and outline the steps to achieve it.

- Address mistakes as they happen; don’t wait to correct them after the fact.

- Before introducing changes, get to the root of the issue to understand its causes. Only then can you resolve it effectively.

- Prioritize ideas that optimize company operations — but avoid perfectionism that impedes progress.

- Create an environment where all stakeholders can share ideas for improvement.

- It’s better to consider suggestions from 10 people than to wait for one brilliant idea from a single individual.

- Once you’ve made a change, use key performance indicators (KPIs) to evaluate its effectiveness. If it proves successful, standardize the modification and apply it in other areas.

- Solve problems on-site. Through genchi genbutsu — “go and see for yourself” — you gain firsthand understanding of the issue and can take appropriate action.

Benefits of kaizen in business

Implementing kaizen fosters a culture of continuous improvement. It brings multiple benefits to organizations that embrace its principles:

- Increased efficiency. Eliminating redundant steps makes manufacturing and distribution more agile, aligning operations with market demand.

- Cost savings. Responsible use of resources — focusing on what truly matters — has a positive impact on the bottom line.

- Improved quality. Identifying current issues and optimizing processes leads to products and services that better meet customer expectations.

- Flexibility. More resilient companies can pivot quickly to changes and unexpected situations, gaining a competitive edge.

- Skill development. Kaizen promotes employee training and professional growth, enabling staff to take on new projects and lead initiatives.

- Positive work environment. Workplaces that involve and motivate employees encourage idea-sharing. This boosts both engagement and overall value to the organization.

- Safer environments. Removing unnecessary steps and implementing more efficient processes helps reduce occupational risks.

Examples of companies that apply kaizen

Several Asian technology companies, including Samsung, have incorporated kaizen-inspired practices. Gemba walks, for instance, are common among executives. This exercise involves observing firsthand the daily operations where value is created in the company — not only when there’s a problem. This approach enables managers to assess the eight areas where inefficiencies most often occur, easily remembered by the acronym TIMWOODS: transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and skills.

Nestlé, a global leader in food and beverages, was one of the first multinational food companies to adopt kaizen. Thanks to this philosophy, the business minimized waste in its production plants and eliminated idle time from processes. Committed to constant improvement through change, Nestlé has long relied on Mecalux’s automated storage and retrieval systems (AS/RS) to maximize the performance of its production centers.

At Interlake Mecalux, we drive order and operational efficiency with storage systems, warehouse automation, and digital solutions aligned with the kaizen philosophy. We also work hand in hand with our clients when implementing our Easy WMS warehouse management system, tailoring it to their needs. If you’re looking to strengthen your supply chain, don’t hesitate to contact us — we’ll help you level up your logistics game.