Warehouse space management and the ecommerce effect

Successful warehouse space management is becoming more difficult by the day due to the numerous challenges of ecommerce logistics. Ecommerce retailers require their logistics facilities to be near big cities to guarantee same-day delivery, optimize the last-mile, and cut transportation costs, among other factors.

A Deloitte study indicates that by 2023, demand for warehousing space will increase by 850 million ft². This upturn in demand is continuing to drive up the already lofty price of logistics square footage. Against this backdrop, companies are forced to optimize their warehouse space management to maximize capacity and reduce costs.

Ecommerce and the need for warehouse space management

Lack of warehouse space is one of logistics managers’ main concerns — even more so with the rise of ecommerce, which has directly affected the industrial real estate market. As a result, logistics real estate — the real estate segment dedicated to the rental and sale of warehouses, industrial facilities, and industrial land — has become a prized commodity.

The first consequence of the ecommerce boom is a lack of logistics floorspace and the ensuing price hike caused by the law of supply and demand. The trend suggests that this lack of warehouse space will continue to climb. According to a study by real estate consulting firm CBRE, an additional 2.1 billion ft² of warehousing will be required over the next five years to support the growth of ecommerce worldwide.

So, why has ecommerce made warehouse space management so important? Ecommerce requires businesses to streamline processes in their facilities to meet the same-day delivery standard ― although there are even logistics services with deliveries in a matter of hours.

One common practice for shortening order delivery times is to bring the warehouse closer to end consumers, who generally live in large urban areas. The facility doesn’t have to be downtown, but it should be near the city to improve efficiency in last-mile delivery, one of the most critical points of ecommerce logistics. A survey from global consulting firm Aberdeen Standard finds that warehouse location is slated to become one of the most crucial factors for a company’s logistics operations. Almost 60% of logistics managers interviewed said that this would be a vital aspect.

The need to move warehouses nearer to cities and optimize storage space due to mushrooming online sales has brought about the concept of microhubs. Micro-fulfillment centers are small logistics centers that are set up near cities and equipped with automated storage systems. These urban microhubs can prepare a large number of orders containing few SKUs, as is typical in ecommerce logistics.

Solutions to optimize ecommerce warehouse space management

Rising demand for logistics square footage is driving ecommerce companies to seek solutions that increase throughput and warehouse capacity in their facilities. These are the most common:

These solutions can expand storage capacity in the facility you manage:

- Multi-tier shelving: storage system formed by one or more levels of walkways supported on the racking itself. The raised aisles are walk-through structures that speed up picking by providing direct access to the goods. This storage solution is popular in ecommerce warehouses, as seen in the facility of online retailer Motobluz.com. The leading motorcycle equipment and accessories business has a four-story logistics center designed by Mecalux with a storage capacity for up to 60,000 items. Multi-tier shelving has enabled the French ecommerce company to make the most of its facility's height, maximizing the available spaces.

- Mezzanines: this storage solution also makes it possible to leverage a building’s height. Unlike multi-tier shelving, mezzanines are self-supporting steel structures formed by columns and girders. Mezzanines make it possible to build a new elevated surface above the floor, providing additional space for shelving. Mezzanines have increased the storage space of companies like ID Logistics, a third-party logistics (3PL) provider whose main customer is one of the world’s largest ecommerce retailers. “The idea to install this warehouse came about because one of our customers wanted to strengthen its presence in Europe. It was looking for a logistics solution that would significantly and effectively boost its storage capacity and accommodate many different types of products,” says Yann Belgy, Managing Director of ID Logistics Poland. The four-level mezzanine set up in this 3PL’s center has been instrumental in increasing its useful storage space by 300%.

- Carton flow racks: ideal storage system for streamlining order picking in facilities with high product turnover (i.e., ecommerce warehouses). Carton flow racks are a gravity-driven storage system with slightly inclined platforms. The goods are deposited on the higher side and slide forward towards the picking aisle. This solution for light loads reduces order picking times and is adaptable to the needs of each facility. For instance, Mecalux installed carton flow racks in the omnichannel warehouse of Admenta in Italy. Together with the other storage systems installed, these racks facilitate the processing of 90,000 order lines a day. “We use the carton flow racks to store small boxes that can be directly handled by operators during picking,” says Enrico De Stefani, Director of Logistics and Business Operations at Admenta.

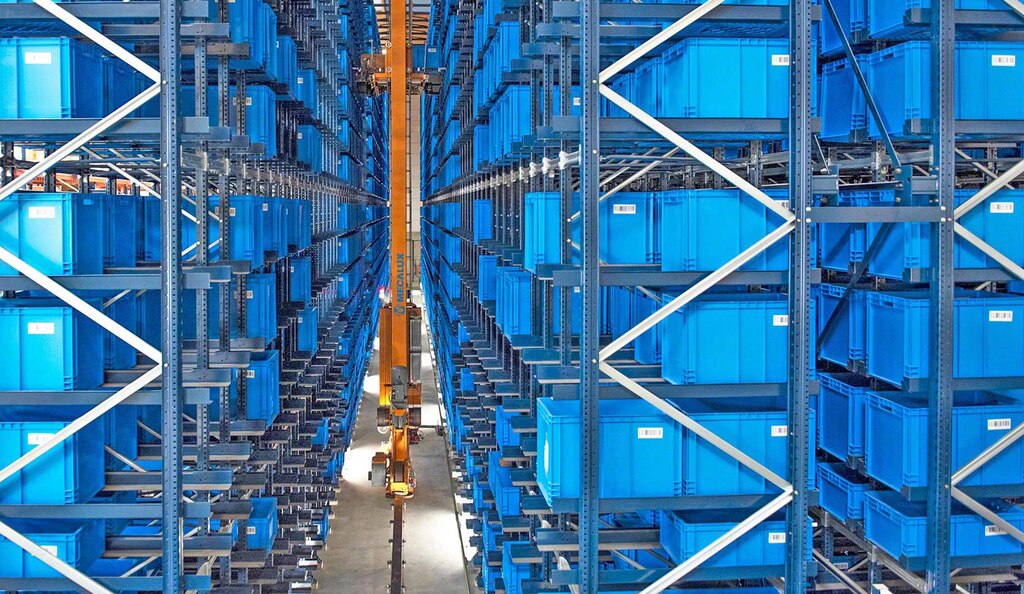

- Mini-load system: solution that integrates racks, stacker cranes (which insert and remove the goods), conveyors, and warehouse management software to coordinate operations. Also known as automated storage and retrieval systems (AS/RS) for boxes, mini-load systems reduce space requirements in ecommerce facilities. What’s more, they control stock in real time and maximize productivity. Mecalux equipped the logistics center of Cofan with an AS/RS for boxes. The online retailer of hardware, plumbing, and industrial supplies increased its storage capacity to 14,334 boxes. Additionally, it set up a specific area for picking according to the goods-to-person method.

- Warehouse management system (WMS): WMS software automates the distribution of stock in the different locations of a facility. It also designs efficient picking routes to ensure that operators travel the shortest possible distances. “With Easy WMS — the software from Mecalux — we can cope with the increased number of orders we’ve seen in recent years. Operators learn to use the management software in record time. The system is so intuitive that, following its instructions, our workers are much faster and don’t make mistakes,” says Gregor Rančnik, CEO of Slovenian ecommerce retailer Gibon.

The warehouse space planning ecommerce companies need

In a context where the scarcity of available industrial land calls for urban distribution centers to guarantee same-day deliveries, logistics managers are faced with the challenge of properly organizing and managing their ecommerce warehouse space.

Likewise, this industrial land shortage pits the sector against soaring prices, pushing retailers to take measures to leverage the space they have without losing efficiency. High-density storage systems and digitization are two tried-and-true solutions for solving the ecommerce logistics space conundrum.

Thanks to our extensive catalog of logistics solutions, Interlake Mecalux is a specialist in installing personalized storage systems and in optimizing space in ecommerce facilities. Get in touch so one of our expert consultants can show you how to get the most out of your warehouse space.