Logistics challenges: Examples and how to overcome them

Supply chain managers face numerous logistics challenges in their efforts to plan, manage, and control goods storage and shipments. What hurdles are they up against in their day-to-day operations, and how do they clear them?

What are the challenges faced by logistics?

Logistics challenges are issues or obstacles that alter the smooth functioning of supply chains. However, they also represent opportunities to transform processes and improve productivity. These problems affect every aspect of logistics, from planning and execution to customer service and human resources. Examples include supply chain disruptions and the implementation of new technologies or work organization methods.

Below are several challenges companies must address and the keys to achieving effective logistics operations.

Automation and digitalization

According to Sergio Coelho, a Senior Director Analyst at the research firm Gartner, pressure to reduce costs continues to be a supply chain challenge. Therefore, companies must prepare for potential disruptions and increasing demand. Developing long-term growth strategies is vital, and visibility through digitalization and automation is central to reaching this goal.

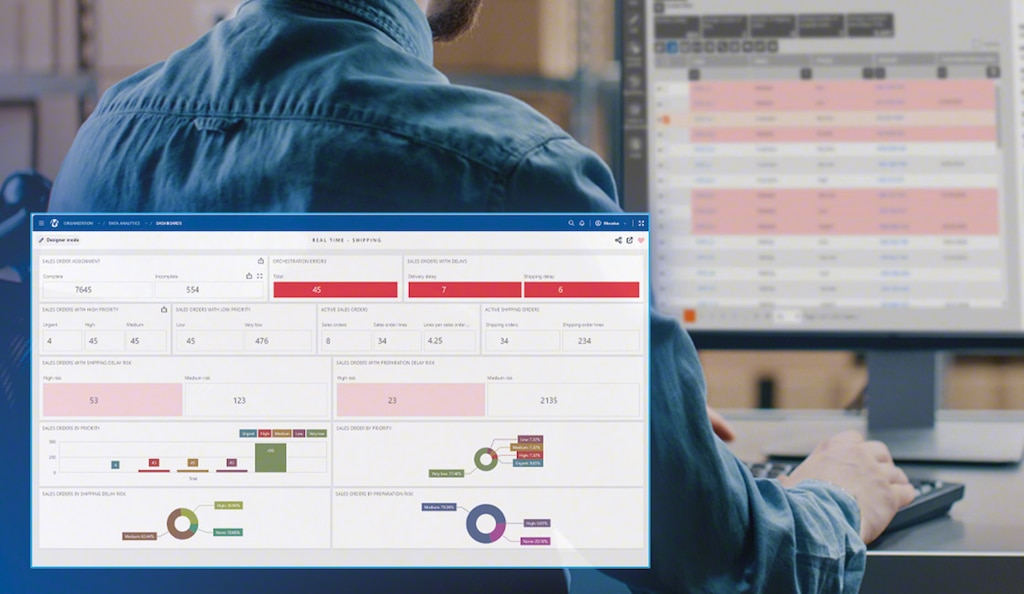

In logistics and warehouse management, demand forecasting relies on collecting and analyzing large volumes of data. To leverage this information effectively, it’s critical to be equipped with automated storage and retrieval systems and specialized software that integrates seamlessly with ERP solutions.

From Logistics 4.0 to 5.0

Businesses are transitioning from Logistics 4.0 — closely tied to big data, artificial intelligence (AI), the Internet of Things, and omnichannel strategies — to Logistics 5.0, which builds on these advancements while focusing on agile customer care.

Logistics 5.0 prioritizes serving hyperconnected customers, often millennials, who count on e-commerce and expect near-instant delivery. Meeting their demands requires top-tier solutions, blending human talent with digital transformation.

Sustainability and the environment

The logistics industry is under increasing pressure to lower carbon emissions and adopt sustainable practices. Environmental regulations are becoming stricter, and as experts like sociologist Leyla Acaroglu have noted, companies need to embrace sustainability — business as usual is not an option. Organizations such as the European Union, aiming for a circular economy by 2050, are introducing new eco-design standards for products sold within their borders. These goods will incorporate a digital passport, providing consumers with comprehensive information about items to enable more informed purchasing decisions.

This paradigm shift affects not only manufacturers and distributors but the entire supply chain. Sustainable logistics seeks to minimize the environmental impact of business activities by using efficient fuels, renewable energies, and green packaging in both distribution and internal logistics operations. Similarly, avoiding returns with tools like Interlake Mecalux’s Easy WMS warehouse management system helps reduce the last-mile delivery footprint.

International trade

Some long-established trade routes are being redefined due to incidents like the 2021 Suez Canal obstruction. Meanwhile, alternatives, including air, rail, and river transport, are increasingly conditioned by events such as pandemics and armed conflicts. Businesses should leverage periods of supply chain stability to mitigate potential delays during crises and prepare for international logistics challenges.

Challenges in the logistics industry

Supply chain managers are also responsible for identifying logistical issues and focusing on the following internal aspects to optimize operations:

- Customer service. A core function of logistics is to deliver products to the right place within the agreed time frame and conditions. Consumers expect transparency about where their orders are and when they’ll be delivered. Thus, enhancing logistics processes improves customer satisfaction.

- Storage costs. Another logistics challenge supply chain directors face is ensuring their facilities operate with the utmost efficiency. To this end, it’s best to rely on warehousing experts and make the most of space through vertical expansion and automated storage and retrieval systems (AS/RSs).

- Demand forecasting. Staying up-to-date on market changes and trends — e.g., new product launches and evolving regulations — is crucial for anticipating customer needs and responding appropriately.

- Supplier management. Logistics involves various stakeholders, so maintaining strong relationships with suppliers is a must to guarantee timely deliveries and access to essential materials for the company.

- Pursuit of operational excellence. The human factor is fundamental to solving logistics problems successfully. Teams need tools that provide the best available information to perform their tasks effectively.

Strategies to overcome logistics challenges

One way to tackle the constant changes in logistics is to focus on the various stages of the process and follow the latest logistics trends:

- Inbound logistics. Optimizing goods receipt, identification, and storage lays the foundation for successful logistics operations. It ensures the proper conditions for implementing automated systems and software.

- Outbound logistics. This covers order fulfillment, consolidation, packaging, shipping, and transportation. To streamline product management, loading, and shipping and coordinate with couriers, companies with several distribution centers and large-scale daily shipments can benefit from a distributed order management system like Easy DOM.

- Reverse logistics. Often overlooked, returns — i.e., reverse logistics — can create bottlenecks if not handled properly. The main goal is to minimize returns of packages to the warehouse. That said, to streamline the process, businesses should have a clear protocol in place.

Tackle your logistics challenges with Interlake Mecalux

Adapting proactively to changes in logistics is the key to success for companies. At Interlake Mecalux, we can help you plan and execute your projects, taking into account your particular logistics concerns. As manufacturers of its own products, the Mecalux Group has implemented thousands of automated and conventional warehouses worldwide since 1966. Its team of over 400 engineers is dedicated to developing logistics software, while the robotics division focuses on the latest fulfillment technologies. Don’t hesitate to contact us for expert advice on this and other storage solutions.