Lean methodology: Principles and business examples

Lean methodology shows that growth doesn’t always require more resources or complexity. Instead, it focuses on eliminating what’s unnecessary through continuous improvement techniques. In this post, we explain what lean methodology is, how it works, and explore its applications in logistics.

What is lean methodology?

Lean methodology is a set of practices designed to streamline how companies organize, produce, and move goods. It aims to make processes more efficient by reducing the resources, time, and effort involved.

At its core, lean is about delivering maximum value to end customers — providing high-quality products and services at the right time and the most competitive cost. Companies achieve this by creating a smooth, uninterrupted value stream and striving constantly for perfection. At the same time, lean fosters a culture of teamwork and mutual respect.

Origins of lean methodology

While lean methodology can be applied to any sector today, it was originally linked to the automotive industry. It dates back to when Kiichiro Toyoda, founder of Toyota, decided to create a new division within his textile company focused on automobile production.

Inspired by Ford’s manufacturing system and the rapid growth of the US auto industry, Toyoda began building his own cars. However, the Second World War led to a drop in demand and forced Toyota to adopt a more flexible production model. In response, company engineers — most notably Taiichi Ohno — sought ways to strip processes down to their essentials to operate more efficiently. This laid the foundation for the Toyota Production System. However, the lean management method didn’t take off among Japanese and American companies until the 1970s and early 1980s.

Core concepts of lean methodology

Lean methodology is built on three key pillars: continuous improvement, value creation, and waste elimination. When applied correctly — and with genuine respect for team members — these principles lead to smarter decision-making, helping organizations become healthier and more productive.

- Waste elimination. This means cutting out anything that doesn’t directly contribute to delivering products customers want or value.

- Continuous improvement. This involves regularly identifying ways to simplify work and reduce waste. Techniques like Six Sigma and the Shingo Model can be used to support this process.

- Value creation. Lean organizations put the customer front and center, engaging in ongoing dialogue to tweak products and services. Likewise, they empower employees to solve problems and make decisions by giving them autonomy, proficiency, and a clear sense of purpose.

What are the 5 principles of lean methodology?

Lean methodology is structured around five core principles that guide effective management:

- Identify value. Start by eliminating anything that fails to benefit customers. The goal is to pinpoint the parts of the product or service that truly matter and focus resources on those areas.

- Map the value stream. Once each team member's contribution is clear, create a value stream map to visualize how materials or information will flow through the process. One way to do this is through kanban boards.

- Establish an optimal workflow. Design a new way of working that enhances execution as well as the final product or service. In addition to eliminating redundant activities, the technologies and tools implemented will perform time-consuming tasks more quickly.

- Use the pull system. Inventory management has a major effect on logistics costs. Unlike push strategies, which produce goods in advance based on forecasts, pull systems respond to actual demand. They trigger production or supply only when needed, boosting efficiency.

- Pursue perfection. True to its commitment to continuous improvement, lean encourages professionals to aim for perfection in their processes. This involves identifying the root causes of issues, collecting performance data, and making changes when necessary. An example would be addressing areas of waste.

How many types of waste does lean identify?

In lean methodology, waste (muda in Japanese) refers to any activity that doesn’t add value to a product or service. These inefficiencies often stem from avoidable issues in production or management.

Lean identifies eight types of waste that can occur in factories, warehouses, distribution centers, or offices when workflows aren’t properly organized. A helpful way to remember them is the acronym TIMWOODS:

- Transportation. Poorly planned — and especially unnecessary — in-house transport wastes time and resources.

- Inventory. Excess raw materials, work-in-progress, and finished goods tie up space and capital, reducing profitability.

- Motion. Unproductive movements of machines or people cause unnecessary wear on products, workers, and handling equipment (e.g., forklifts). Warehouse automation can help lean businesses reduce double handling.

- Waiting. Long wait times slow productivity. This includes delays in receiving materials, information, and approvals. If prolonged, they can impact end customers and harm a company’s reputation.

- Overproduction. Producing more than is needed causes overstock. Avoiding this requires accurate forecasting, optimized methods, and robust warehouse management tools.

- Overprocessing. Performing non-value-adding tasks complicates workflows and generates waste.

- Defects. Faulty products damage customer satisfaction and lead to costly returns or replacements.

- Skills. Failing to tap into employees’ knowledge, creativity, and abilities wastes human capital. This can be avoided by actively involving staff in continuous improvement efforts.

Lean methodology in logistics

Lean principles can also be applied in logistics. This approach, known as lean logistics, is reflected in several key areas:

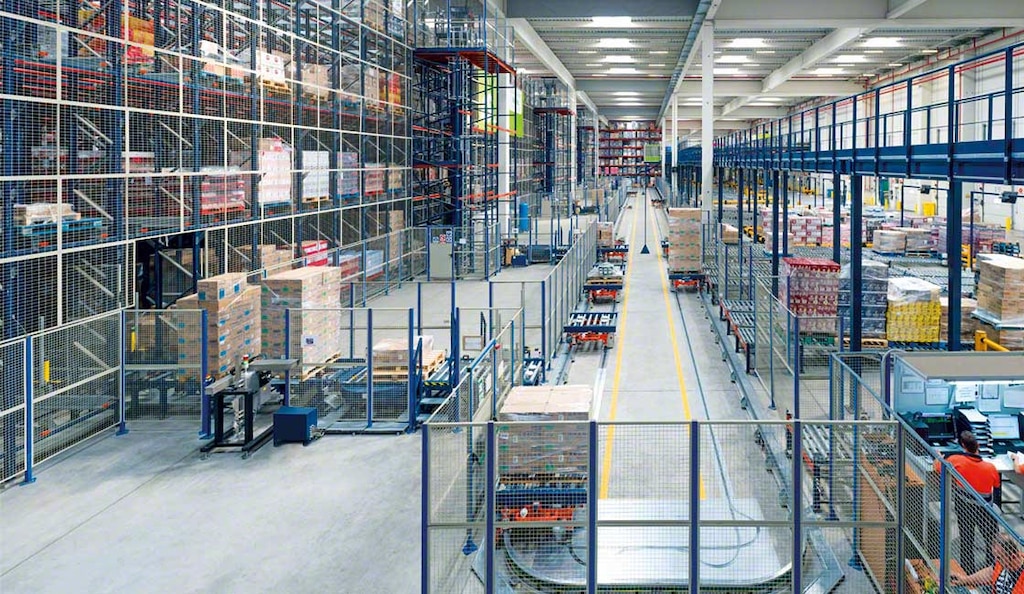

- Warehouse automation. Automating material handling is crucial for internal logistics operations. It shortens intralogistics transport times while enhancing safety. Automation is especially valuable for repetitive flows, where solutions such as stacker cranes streamline every movement.

- Order fulfillment. Careful planning of picking activities minimizes unnecessary travel. A warehouse management system (WMS) helps organize efficient pick paths and consolidate goods throughout putaway, picking, labeling, and packaging.

- Reverse logistics. Order processing errors often lead to high return rates. Implementing a WMS can significantly lower these mistakes, raising overall service quality.

Ultimately, lean methodology promotes the free flow of information and ideas among team members. Organizations that master lean naturally embed efficiency and waste elimination into their processes, increasing their levels of productivity and innovation.

Lean methodology in 5 questions

What is lean methodology?

Lean methodology optimizes business organization, production, and logistics by reducing investments, time, and effort to make processes more effective. Its goal is to maximize value for customers.

What are the core ideals of lean?

Lean methodology is based on continuous improvement to simplify work and reduce waste. This leads to smarter decisions and healthier, more productive companies.

What are the principles of lean?

Lean methodology follows five principles: identify value, map the value stream, optimize the workflow, use the pull system, and pursue perfection. These principles aim to eliminate the unnecessary, maximize processes, and respond to actual demand to achieve excellence.

What wastes does lean identify?

Lean highlights eight wastes in work organization: transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and underutilized skills. Minimizing these wastes makes the most of resources while increasing productivity and customer satisfaction.

How is lean applied in logistics?

Lean methods are applied to the supply chain through technologies like warehouse automation, efficient planning, and error reduction with WMS software.