How to reduce returns in ecommerce

Understanding how to reduce product returns in ecommerce helps companies design efficient, customer-focused strategies. Businesses that can anticipate buyer expectations and needs ensure a more satisfactory shopping experience. In today’s competitive online landscape, every detail — from product presentation to after-sales support — plays a fundamental role in limiting issues and boosting profitability.

This post explores why ecommerce returns occur and how automation and software solutions can keep them at bay.

Main causes of e-commerce returns

The most common reasons for returns include manufacturing defects, unclear product descriptions, and issues related to sellers or carriers. Identifying these factors allows businesses to address quality problems, clarify product information, and improve logistics flow.

According to an international DHL survey of 12,000 consumers across 24 countries, sizing errors top the list (26%), followed by defects or quality issues (23%), shipping damage (15%), poor fit/unsuitability (13%), and discrepancies with online images (10%). Smaller percentages of users reported ordering multiple options to compare (6%), buying more than necessary (3%), or simply changing their minds (4%).

While the DHL survey reflects the consumer perspective, research from Sungkyunkwan University highlights the business side. Flexible return policies and minimum-purchase discounts drive sales but can also encourage impulse buying or strategic purchases, leading to more returns.

How to calculate the return rate in ecommerce

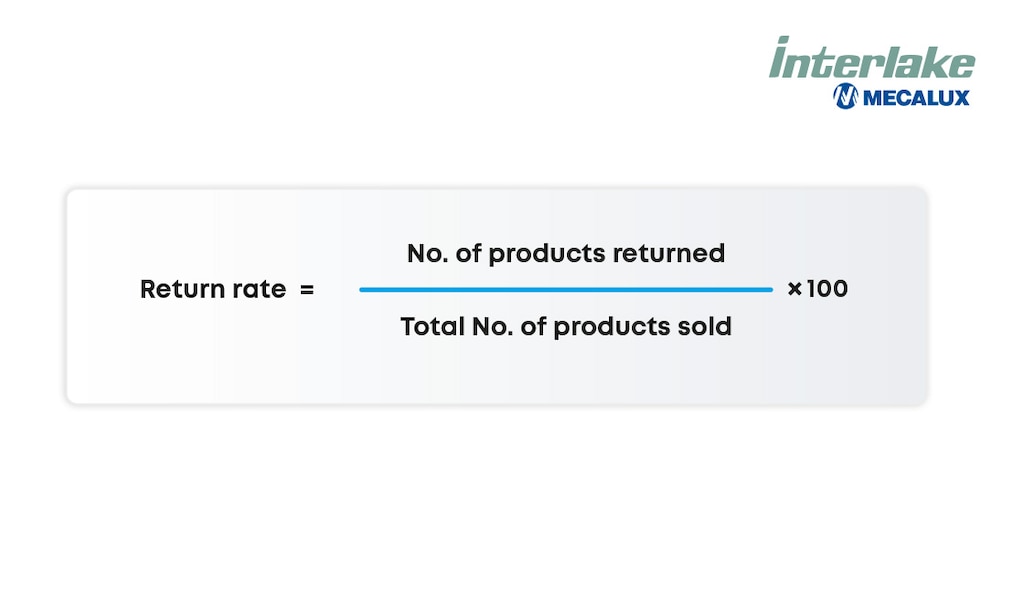

The product return rate formula measures the percentage of items sent back by customers after purchase. This key performance indicator (KPI) reflects the relationship between returned units and total sales over a given period.

This KPI is much more than a simple statistic: it reveals customer satisfaction and operational efficiency. High rates often point to issues with catalog accuracy, marketing communication, product/service quality, or logistics management. To maintain healthy profit margins, companies must carefully analyze their returns management costs, such as packaging, transportation, inspection, and refurbishment.

How to reduce product returns

There’s no single answer to how to reduce customer returns. Success depends on a holistic strategy encompassing everything from product display to post-sale service. These key actions can help you achieve this:

- Transparent return policy. Clear, accessible policies avoid misunderstandings. Include deadlines for returns, product condition requirements, step-by-step instructions, and available channels. Clarify what can be returned, exchanged, or credited.

- Accurate product descriptions. Comprehensive information helps align customer expectations with reality. Display dimensions, weight, materials, and size guides (for apparel and footwear). Videos can effectively convey texture and functionality.

- Customer feedback and photos. User-generated content (reviews and real-life images) builds credibility and trust, showing how products are actually used.

- Secure shipping. Suitable and sufficiently robust packaging ensures that items arrive intact. While carriers bear some responsibility, sellers can take precautions: checking product condition before shipment, using protective materials (bubble wrap or dividers), and selecting suitable boxes.

- Customer support. Efficient support prevents and resolves issues. Offer pre-purchase advice on sizing, compatibility, or technical features. Post-sale, maintain fast, accessible channels to update customers on return progress in real time. Collect feedback after completion to gather insights for improvement.

In addition to these customer-oriented actions, companies should also apply warehouse best practices:

- Proper storage. Maintaining merchandise in optimal conditions avoids damage and deterioration.

- Optimized picking operations. Streamlining order processing limits handling errors and shipment issues.

- Automation of critical processes. Automated storage and internal transport solutions minimize damage and mistakes, resulting in fewer returns.

- Traceability. Tracking each item from receipt to delivery helps identify and correct inefficiencies before they escalate.

The role of automation in reducing returns

US retailers expect 19.3% of annual sales to be returned in 2025 — valued at $849.9 billion. These figures come from the National Retail Federation (NRF), the world’s largest trade association in the sector. Free returns remain a decisive factor for 82% of shoppers, while over two-thirds of businesses plan to enhance after-sales processes in the coming months. Against this backdrop, automation and robotics offer an efficient way to prevent errors and returns.

A Kingston College study found that automated storage and retrieval systems (AS/RS) for pallets, picking robots, and autonomous mobile robots (AMRs) significantly improve order accuracy. The operational efficiency these solutions bring helps minimize one of the main reasons for ecommerce product returns: orders shipped with errors. The authors underline that these technologies enable higher fulfillment volumes with less human intervention, limiting shipment mistakes and, consequently, returns.

Automation supports goods-to-person workflows, where material handling equipment delivers products directly to warehouse associates. Solutions like stacker cranes, shuttle systems, high-performance pick stations, and picking robots boost speed, accuracy, and efficiency. Research from Beijing Geely University on e-commerce logistics highlights three benefits of the goods-to-person method for picking and packaging: faster, higher-quality performance (with a throughput three to five times greater than manual operations), error rates lowered to below 0.5%, and optimized material utilization (with efficiency increased by 20%).

Warehouse management systems (WMSs) and distributed order management (DOM) software are also essential in thwarting returns. The WMS coordinates every move made in a facility. It ensures full traceability, providing associates with precise instructions to avoid picking errors — one of the main causes of ecommerce returns. Meanwhile, the DOM system optimizes multichannel fulfillment, selecting the best shipping points in real time according to inventory location, operational capacity, and delivery timelines. This precision prevents delays and incorrect shipments.

Some WMSs offer advanced modules to reduce returns even further. Interlake Mecalux’s Easy WMS, for instance, features Multi-Carrier Shipping Software. This module selects the ideal transportation provider according to the delivery zone, cost, service level, and other criteria. Another Easy WMS tool is the Value-Added Services (VAS) module, which tailors orders to customer specifications. Finally, Marketplace Integration syncs actual inventory with sales platform listings to eliminate incorrect shipments.

Real-world examples of companies that have reduced returns

Numerous businesses have slashed their return rates after implementing Mecalux Group software and automation solutions:

- Stand-Privé.com. Shipping more than 2,600 orders a day entails a high risk of making mistakes. To mitigate this, the French fashion e-tailer implemented Easy WMS. The software guides staff on what to pick and where to place it. “With Easy WMS, our associates no longer make mistakes, and we’ve minimized customer returns,” says a founding partner.

- Rent a Book. The Belgian textbook rental and sales company manages high order volumes in short periods. Easy WMS organizes and supervises operations to ensure timely, accurate fulfillment. “Since deploying the Mecalux WMS, we’ve seen fewer returns than in previous years,” say Rent a Book representatives.

- Agro-Masz. This Polish agricultural machinery manufacturer oversees an extensive catalog of metal parts and components. To optimize its operations, it automated its warehouse with a mini-load system (AS/RS for boxes), a high-performance pick station, and Easy WMS. Real-time inventory control and traceability limit errors and thus returns.

Reducing returns, building customer confidence

As e-commerce continues to grow and consumers demand speed and reliability, companies that digitalize their warehouse operations will gain a competitive edge. Reducing ecommerce returns relies on precise logistics operations, transparent information, and advanced technology. Automation and software solutions like WMS and DOM provide real-time data, eliminate mistakes, and offer complete traceability to delivery. These tools transform logistics processes into a strategic advantage, boosting profitability and the customer experience.

How to reduce returns in ecommerce, in 5 questions

What are product returns?

Merchandise that customers purchase and then send back due to order errors, defects, sizing issues, or mismatches with expectations.

What is the return rate?

The return rate measures the percentage of sold products that customers send back. To calculate it, divide the number of returned items by the total number of items sold and multiply by 100. This KPI reflects customer satisfaction, product quality, and logistics efficiency in ecommerce.

Which KPIs help reduce returns?

Companies should monitor KPIs like return rate and mispick rate (percentage of order picking errors) to detect recurring issues and make improvements.

What common mistakes cause returns?

Frequent errors include quality defects, shipping damage, mismatched descriptions or images, and mispicks.

What solutions help reduce returns?

This calls for combining several strategies: detailed product listings, secure packaging, effective customer support, WMS and DOM systems, and automated handling equipment to enhance accuracy and traceability.