What is total productive maintenance? Implementing TPM in business

Total productive maintenance (TPM) is one of the many asset management strategies employed in industry today. Originating in Japan, it represents not only a maintenance methodology but a philosophy capable of reshaping an organization’s culture. When applied consistently, it has the potential to boost efficiency, quality, and productivity while reinforcing workplace safety and collective responsibility.

In this post, we examine what total productive maintenance is and the eight pillars it’s built on. Additionally, we outline the pros and cons of TPM and explain how to implement it effectively.

Total productive maintenance definition

Total productive maintenance (TPM) is a continuous improvement methodology focused on keeping equipment in optimal condition. It promotes efficient asset management through the shared participation of every employee — not just the maintenance staff. Everyone contributes to a safe, productive workspace by carrying out regular inspections, predictive maintenance tasks, and equipment checks.

The objectives of TPM are to make the most of each machine, achieve higher production rates, and eliminate financial losses tied to downtime and quality issues. Ultimately, total productive maintenance strives for the three zeroes: zero defects, zero breakdowns, and zero accidents. Japanese engineer Seiichi Nakajima, author of several books on TPM, is considered the founder of this system.

The 8 pillars of total productive maintenance

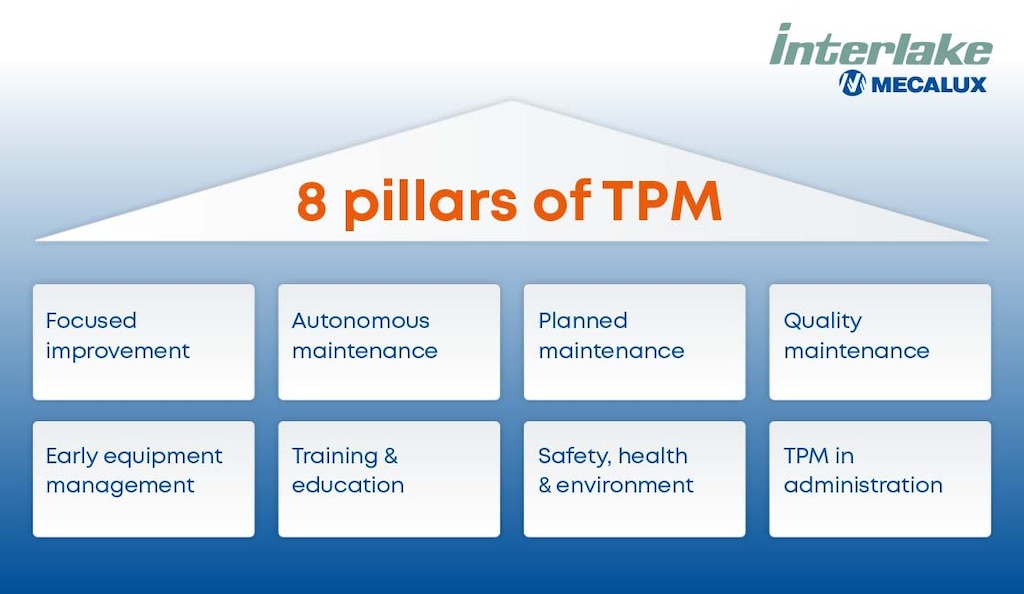

One of the key features of TPM is its structure around eight foundational pillars, often represented as parts of a single building.

- Focused improvement (Kobetsu kaizen). Teams identify opportunities for gradual improvement to reduce losses and enhance process efficiency.

- Autonomous maintenance (Jishu-hozen). Operators take responsibility for their machines, performing inspections, cleaning, and maintenance. Empowering workers to spot early signs of failure is crucial here.

- Planned maintenance (Keikaku-hozen). Regular inspections and maintenance help detect potential issues before they occur.

- Quality maintenance (Hinshitsu-hozen). Teams ensure that equipment delivers flawless output. When defects do appear, quality management practices help trace their root cause.

- Early equipment management. TPM encourages applying lessons learned from experience to the design of new machines, facilities, and processes. In some cases, redesigning production lines or adopting new technologies can accelerate results.

- Training and education (Kyoiku Training). Workers must receive training to operate equipment effectively, improve their skills, and update procedures when needed.

- Safety, health, and environment (SHE). Clear protocols support worker safety, proper use of protective gear, and control of environmental conditions during machine operation.

- TPM in administration (Office TPM). The methodology also applies to administrative areas, extending to inventory management and logistics process optimization. Managers leverage the information obtained, sharing it across departments to foster a continuous improvement culture throughout the company.

Pros and cons of TPM

Major corporations such as Toyota and Nippon Steel have proven that implementing total productive management brings multiple benefits:

- Higher process quality translates into better products and profitability.

- Shared maintenance responsibility extends equipment lifespan.

- Operational efficiency increases through reduced downtime/machinery failure.

- Fewer accidents mean safer workplaces.

- Employees build valuable skills and confidence.

- Seeking potential solutions fosters teamwork and problem-solving.

- The organizational culture revolves around continuous improvement.

Nevertheless, adopting total productive management also presents challenges. Initial costs can involve staff training and process restructuring. Resistance to change is another obstacle; if employees don’t understand the advantages of total productive maintenance or feel overloaded, sustaining engagement becomes difficult. Finally, maintaining consistency over time is essential to prevent early gains from dwindling.

Example of TPM implementation

Because total productive maintenance calls for profound organizational changes, introducing it requires top management’s commitment. A successful TPM rollout can be structured into five main stages:

- Create a pilot team. Start small by applying changes to one process area, making future expansion easier.

- Optimize performance. Before fully deploying TPM, ensure machines operate at their best. Both maintenance and operating teams should apply the 5S methodology.

- Assess performance. Identify unplanned stoppages over at least two weeks.

- Investigate root causes. TPM training should include problem-solving techniques and fault-detection tools. This is the first step to correcting issues effectively.

- Adopt a proactive mindset. Beyond metrics and targets, empower employees to prevent failures before they occur.

A classic example of TPM in business comes from Toyota Motor Corporation in the 1970s. The Japanese company was the first to apply total productive maintenance, creating a systematic quality control (SQC) team dedicated to this initiative. This group developed checklists and conducted regular audits along vehicle assembly lines. The results were remarkable: improved product quality, reduced equipment costs, and higher employee morale thanks to greater autonomy.

Today, organizations such as Bosch Mobility China use total productive maintenance to predict welding electrode wear through historical data and artificial intelligence. This approach boosts both productivity and overall equipment effectiveness (OEE). In warehouse environments, Interlake Mecalux provides life cycle management services designed to reinforce proactive, ongoing maintenance.

Total productive maintenance: Teamwork and continuous improvement

In essence, the TPM methodology stands out for its ability to merge the principles of continuous improvement with innovative technology. It also places people at the core — promoting autonomy, efficiency, education, and safety through active participation in maintenance and prevention tasks. Once the initial implementation phases are completed, companies that secure team commitment can establish lasting foundations for productivity growth.

Total productive maintenance (TPM) in 5 questions

What is total productive maintenance?

Total productive maintenance (TPM) is a continuous improvement methodology focused on keeping equipment in prime condition. Its implementation improves efficiency, throughput, product quality, and workplace safety.

What is the philosophy behind total productive maintenance?

TPM assumes that equipment maintenance is everyone’s responsibility — not just one department’s. The entire workforce strives to achieve the three zeros: zero breakdowns, zero defects, and zero accidents.

What are the goals of TPM?

Total productive maintenance aims to maximize equipment effectiveness; engage employees through training and participation; promote improvement across production, engineering, and maintenance; and boost performance while lowering operational costs.

What are the pillars of TPM?

The eight pillars of TPM include focused improvement; autonomous, planned, and quality maintenance; early equipment management; training and education; safety, health, and environment (SHE); and TPM in administration (office TPM).

Who is Seiichi Nakajima?

Japanese engineer Seiichi Nakajima is regarded as the founder of total productive maintenance and an early pioneer of overall equipment effectiveness (OEE) in the 1970s. Through the Japan Institute of Plant Maintenance (JIPM), he encouraged full employee participation in equipment care. His 1988 book Introduction to TPM remains a benchmark, and his contributions earned him the Medal of Honor with Blue Ribbon from the Emperor of Japan.