Procurement in logistics: the key to efficient service

There’s a very close link between procurement in logistics and the service a company offers, as all businesses need to be supplied in advance with the resources they require to perform their activity. Procurement is related to the continuous flow of supplies, materials and services. For it to be efficient, proper stock management is crucial.

When organizing the procurement of stock in the warehouse, you have to ask yourself: when should I place an order and how many units of each product do I need? In this post, we answer those questions, in addition to analyzing the procurement cycle (or procurement process) and detailing the operations involved in it.

Definition of procurement in logistics

Procurement is defined as the logistics operation responsible for supplying raw materials or goods in general to a warehouse, logistics center, production plant, or store to ensure that the business activity (production, distribution, or sale) is properly carried out. The concept of procurement in logistics is also associated with terms such as supply and purchasing.

From a warehouse standpoint, procurement relates to the reorder point. When the stock of a certain SKU is below the preset level (established by the EOQ formula, for example), a purchase or replenishment order should then be triggered to prevent a stockout from occurring, as that could lead to a loss of sales or even halt production. Therefore, procurement management is vital for business development.

Procurement cycle

The procurement process or cycle encompasses all operations from the moment the purchase or request for stock is made until the product is received at the facility (warehouse, production center, or store).

This cycle varies depending on whether the organization is a manufacturing/industrial company or a business enterprise.

- Production or industrial company: the procurement process connects the warehouse with the production center. Raw materials are housed on the racks until required by the production lines. Once the raw materials are transformed into the final product, this is stored awaiting dispatch.

- Business enterprise: in this case, the procurement cycle is simpler, as the product stored doesn’t have to be changed in any way. The company purchases and stores the already finished goods until they are shipped to the end customer, to a physical store, or to another facility.

What operations does procurement include?

To implement procurement effectively, you need to take into account the following operations:

- Needs analysis. What resources does the company require to carry out its activity over a specific period of time? It’s important to establish the amount of materials, supplies, and services necessary for manufacturing or selling a product.

- Purchasing. Through this transaction, you’ll obtain the appropriate quantities of the resources and services required at the lowest possible cost. It’s essential to choose a supplier that ensures, in addition to a competitive price, the agreed-upon quality and delivery dates. Here, lead time is a decisive factor.

- Goods receipt and storage. The resources arrive at the docking area and are housed on the racks until they are needed at the production lines. Finished goods are also stored once they leave the production center.

- Supply and dispatch. It’s necessary to feed the production plant with the resources required to guarantee uninterrupted activity. At the same time, the goods that will supply another warehouse or brick-and-mortar store have to be dispatched. At this point, efficiency is especially important: overstock can cause bottlenecks, not to mention increased storage costs.

- Inventory management. Proficient stock management directly affects the throughput of all the operations that make up the procurement cycle.

Operations relating to procurement concern multiple company departments: from administration and purchasing, charged with planning the acquisition of the products, to the logistics team, which handles the dispatch of the goods to customers. Organization and coordination between each of the operations is fundamental for optimal procurement.

Issues with inefficient procurement

If procurement isn’t managed well, you run the risk of having serious problems. The most common are:

- Shortages or stockouts. Finding yourself without stock means lost sales, reduced productivity, or, worst case scenario, production downtime due to a shortfall of the resources necessary for this activity. It’s advisable to be equipped with safety stock that will enable you to deal with any unforeseen events linked to changes in demand and, thus, avoid stockouts.

- Dead stock. This happens when you’ve purchased more goods than you need and they wind up turning into obsolete stock, entailing unnecessary storage expenses.

- Dependence on suppliers. This tends to happen when companies employ the just-in-time procurement method. With this technique, supplies are bought as they are needed. As a result, any incidents with suppliers will impact the entire procurement cycle.

All problems stemming from inefficient procurement processes have a common consequence: a significant rise in operating costs. Good procurement management makes it possible to offer more affordable prices and better service and, ultimately, to be more competitive.

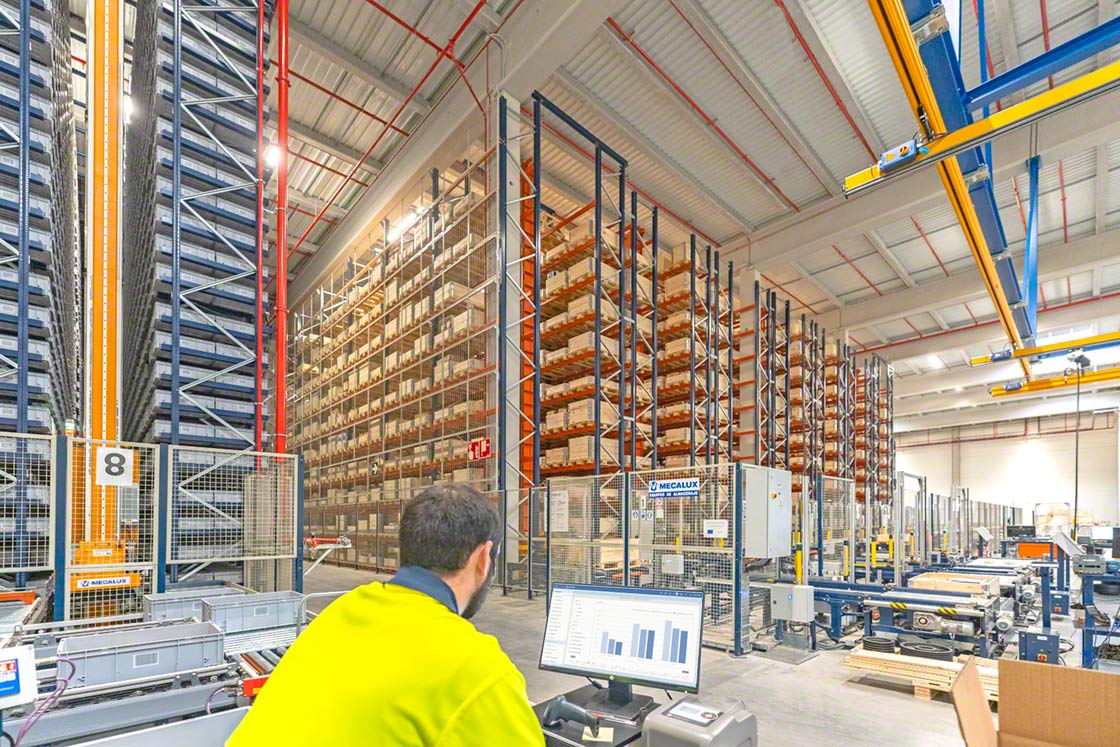

Procurement with a WMS

Can you improve procurement management with a warehouse management system? The answer is a resounding yes. Having an organized and coordinated facility is a must for managing procurement in a way that’s efficient and profitable for the company.

A WMS lets you manage the stock levels based on the just-in-time supply strategy, synced with production or in line with safety stock.

For example, Easy WMS from Interlake Mecalux features the WMS for Manufacturing module, which guarantees the continuous supply of raw materials to the production lines, as it syncs the supply and production buffers. This involves close monitoring of the status of the raw materials and of the exact quantity used in each stage. Among many other functions, this module manages the bill of materials (BOM), a complete list of the raw materials, parts, and tools needed to manufacture a particular product.

Likewise, the system, connected to a MES (manufacturing execution system), not only syncs warehouse operations with production processes to ensure their supply, but also provides traceability of all processes and real-time visibility of the items.

The best supply chain ally

Procurement management is one of the most critical tasks in the entire supply chain. Controlling inventory to determine the amount of stock to work with — as well as the frequency of supply orders to meet production needs — is more complex than it seems.

Interlake Mecalux offers the best logistics solutions, in terms of both storage and management, for achieving efficient procurement management. If, for you, process digitization is synonymous with success and business profitability, don’t hesitate to get in touch with Interlake Mecalux. We’ll help you find the logistics solution that best fits your needs.