Rack-supported warehouses can be built in which goods are handled by free-moving forklifts (trilateral turrets, bilateral turrets or reach trucks).

Nonetheless, one must bear in mind that turret-type devices cannot exceed 50' in height and reach trucks 34'. In addition, wider aisles than those normally used for stacker cranes are needed. A very flat floor is also essential, particularly if using turret-type trucks.

An important factor is that personnel are required inside the racking units to handle the load and perform operations.

Despite these issues, a rack-supported warehouse with free-moving machines is a good option and a worthwhile one too, since it is a specific construction, without pillars, and generally cheaper and faster to build than conventional building systems.

Rack-supported cold chamber with free-moving forklifts.

Supports for free-moving forklifts

Free-moving devices sit directly on the ground and, for safer, faster operations in the aisles, the turret-type truck requires a guidance system. This can be mechanical, wire-guided, or laser-guided (see section on “Handling equipment”).

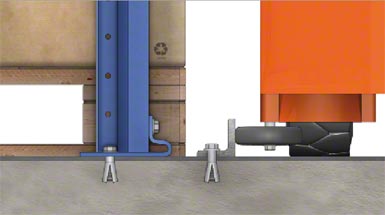

Guided with LPN 50 rail

Guided with UPN 50 rail

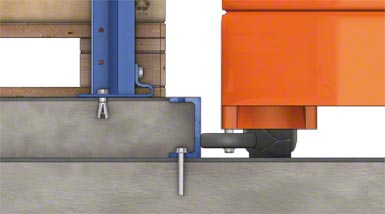

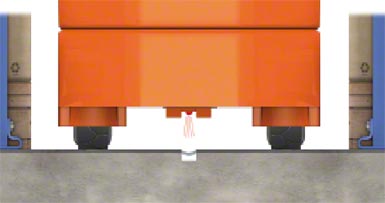

Guided with UPN 100 rail forming island

Wire-guided

Clearances for free-moving devices

The clearances for free-moving devices are very similar to those for their fixed-route counterparts. However, one must remember that the method used to collect and deposit loads used by the first group differs from that used by the second group.

In general, free-moving devices have turning heads to collect and deposit loads on the left or right side of the racking unit. In contrast, fixed-route devices use telescopic heads.

This characteristic means that the needs in terms of aisle width are significantly different. When using 48" deep europallets, a turret truck will need an aisle of 67" to 74" wide, depending on the efficiency achieved with the device, while a stacker crane will need an aisle only 59" to 63" wide.

When specifying clearances in a warehouse designed to be operated with a turret-type truck, one must consider three measures when determining the width of the aisle: the distance between the fronts of the guide rails (marked as A in the accompanying illustration), the length between the fronts of the loads (B), and the separation of the fronts of the racking units (C).

One must also take into account the tolerances of the flatness of the floor discussed earlier.