Seismic racking for pallets and their design

Seismic racks are storage structures prepared to resist any ground motion that occurs.

In this post, we take a look at racking in warehouses located in earthquake zones, examining the way in which it’s designed specifically to withstand the dynamic forces produced by a seismic event.

Earthquake-proof systems in the world’s main seismic areas

Warehouses located in seismic hazard zones could be subject to the effects of an earthquake. For this reason, the racking should have a seismic-resistant structure that reinforces and ensures its optimal performance in the event of ground motion.

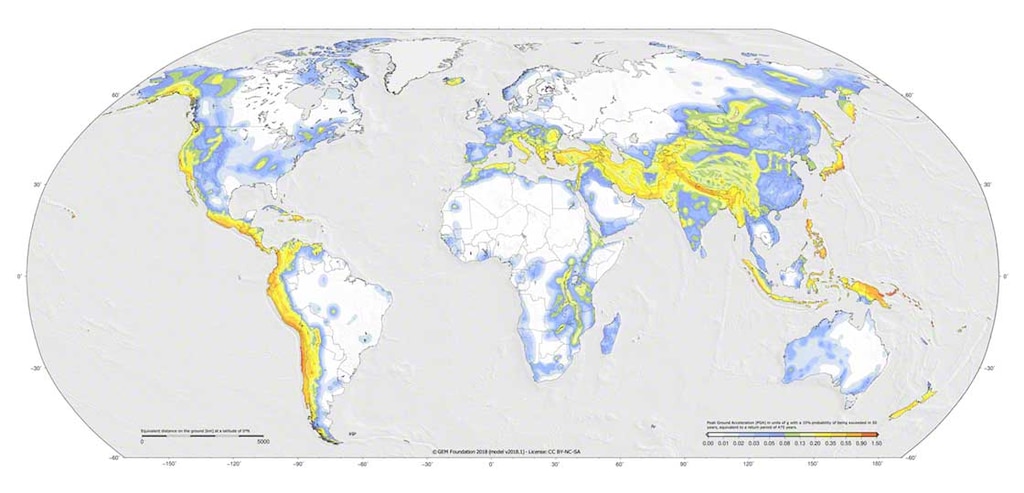

Areas with a higher probability of earthquakes tend to be close to the boundaries of the Earth's tectonic plates. In the case of Europe, for instance, countries at the greatest risk of a seismic event are Italy, Greece, Turkey, Cyprus, and Iceland. The region with the highest seismic probability on the planet is what is known as the Pacific Ring of Fire. It includes Argentina, Chile, Peru, Ecuador, and Colombia, as well as Russia, Japan, Taiwan, Indonesia, and Singapore.

According to the United States Geological Survey’s National Earthquake Information Center, every year, around 20,000 earthquakes occur around the world (some 55 a day).

How can an earthquake affect a logistics center?

An earthquake is a natural vibration — normally of short duration and variable intensity — that happens due to a sudden release of energy. The vibrations arising from a seism are transmitted in all directions in the form of seismic waves. In a logistics center, an earthquake can cause:

- Material damage: the loss or deterioration of goods, in addition to damage to the warehousing structures and equipment, can lead to problems when it comes to covering demand and serving customers.

- Financial damage: the company incurs financial costs when there is damage to goods and property. In logistics systems nowadays, which are flexible and integrated, the risk of disruption could mean financial losses for all links in the supply chain.

- Human damage: earthquakes are capable, unfortunately, of creating the worst harm possible. Warehouses typically work with heavy loads that could jeopardize the physical integrity of operators in the event of an earthquake.

Seismic racking: structural design requirements

Compared to the loads they support, seismic racks are lightweight structures. To design racks for regions with a high risk of earthquakes, it’s necessary to apply specific procedures. In these areas, seismic-proof storage systems must meet three fundamental requirements:

- No-collapse requirement: the structure must be designed to resist seismic action while remaining intact. To guarantee this, it is essential to calculate the forces that the racking components can withstand to verify their ability to resist seismic movements.

- Unit load movement: peak ground acceleration can cause the unit loads to slide on the beams and, ultimately, fall off. This risk could be avoided by attaching cross-ties or mesh panels to the rack beams.

- Damage limitation requirement: although the racks are designed to withstand an earthquake, before using them once again after the event, it’s mandatory to assess the level of damage occurred and to take the necessary measures.

How is seismic racking designed?

Seismic racking is designed in two stages: the first serves to know the dynamic of the racking (how it behaves), and the second consists of calculating the effect of an earthquake on the racks.

First phase

The first study consists of ascertaining the natural dynamic of the structure, that is, the movements of the racks themselves when disrupted.

The natural movements of the racking depend on the relationship between mass and stiffness. Mass relates to the weight of unit loads on the racks and of the racking itself. Stiffness refers to the resistance of the racking to being displaced by horizontal movements.

With this analysis, engineers can determine how an earthquake will affect the racking structure.

Second phase

In the second analysis, engineers study the way in which seismic action affects the racking. Seismic action in an area is defined by the peak ground acceleration, that is, the speed at which the surface area can move taking into account the type of soil (geological formation: rock, very dense sand deposits, soft soil, or loose soil).

The seismic action is obtained from the study of the geographic areas and of the assessment of historical seismic events in the area, information found in the legislation in force in each country. The seismic action could be increased based on the particular characteristics of the facility. These might include risks for people (public access racks), the type of good stored (liquids), or the storage conditions (freezer store).

Examples of seismic racks in warehouses

The Mecalux Group has extensive experience designing earthquake-proof racking for logistics facilities in regions with high seismic activity. These are several projects for which the Mecalux Group has installed racks specifically designed to withstand any possible seismic movement produced:

Brivio & Viganò (Italy)

Mecalux has equipped seven freezer warehouses for Brivio & Viganò — a logistics provider specializing in food products — with pallet racks and push-back racking systems.

Complicating this project was the fact that the logistics center is located in the earthquake zone of Pozzuolo Martesana, Italy. The two storage systems were particularly designed not only to provide the greatest possible storage capacity, but also absorb the force generated by potential ground motion.

According to Managing Partner Stefano Brivio, the solutions proposed were adapted to the company’s requirements because “they have the right seismic resistance and have helped to notably optimize our floor space.”

Iron Mountain (Chile)

In February 2010, an 8.8-magnitude earthquake shook Chile. Five months before that, the Mecalux Group had started-up a warehouse for leading records management business Iron Mountain.

Following the earthquake, the company lost seven of its facilities containing racking from other manufacturers; however, the warehouse outfitted by our company was still standing. Consequently, Iron Mountain called on Mecalux to rebuild its seven damaged facilities and to commission two new warehouses of similar characteristics.

Hayat Kimya (Turkey)

In Izmit, Turkey, consumer goods manufacturer Hayat Kimya has an enormous automated rack-supported warehouse: 390 feet long, 345 feet wide, and 150 feet high.

Turkey sits in one of the most active seismic regions on the planet. Thus, the racking is specifically designed and made to resist earthquakes. The Mecalux Group used 11,000 tons of steel (including 2,200 additional tons of anti-seismic reinforcing steel) and reinforced anchoring.

Pallet racking in seismic areas: the secret lies in the design

Setting up a warehouse in a seismic zone is definitely a logistics challenge. It requires the optimal design of storage systems to guarantee that they are capable of resisting the forces caused by an earthquake.

The Mecalux Group is a world leading storage solutions manufacturer that stands out for its quality and safety standards. The Group uses advanced software to design seismic racking, employing top quality materials to manufacture its racks complying with the anti-seismic regulations applicable in each country. Get in touch if you need seismic racking to ensure the integrity of your logistics facility, of the products stored in it, and, above all, of the people who work in it.