Warehouse material flows and flowcharts respond to one of its basic characteristics, since products stay temporarily inside a warehouse and everything that enters the installation must exit. This flow in a warehouse can be simple or complex, depending on each company, the degree of automated systems, the in-house operations carried out with the goods, the quantity there is of it and the way it is moved. The different material flows can be illustrated through simple flowcharts or flow diagrams.

Types of flows

Flows are the movements of the units as they enter the warehouse, move around it, and finally exit.

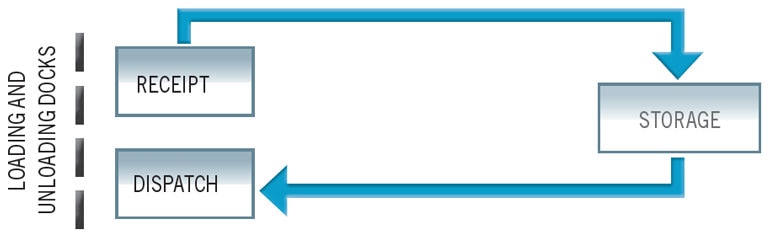

Simple flows: To understand how these movements work, we can examine the simplest possible flow, which takes place when units sent by the supplier are used, without dividing these up.

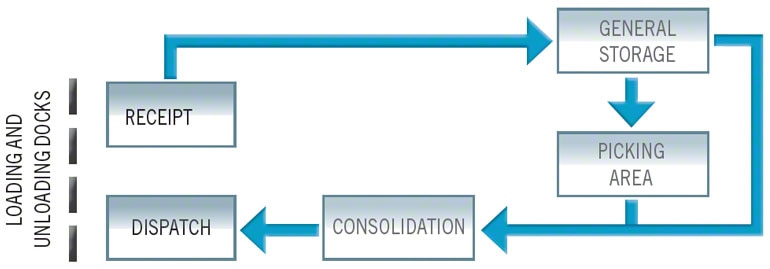

Medium flows: Movements start to become more complex with this type of flow. It is normally found in warehouses with single or combined picking operations, generally with the supply of full pallets.

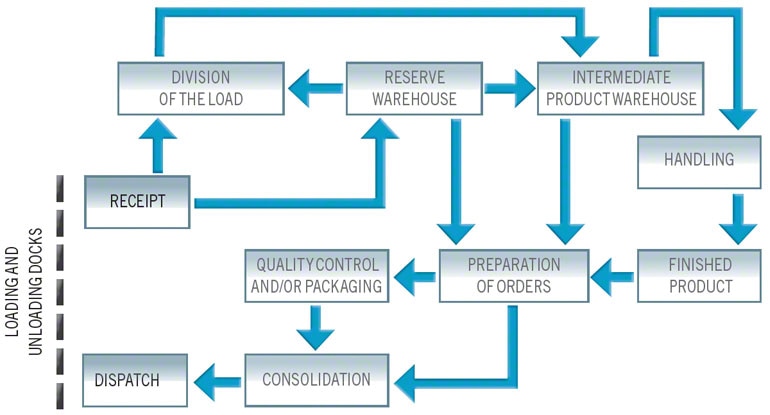

Complex flows: There are warehouses with different working areas, depending on the types of product and their consumption. They normally have intermediate handling areas and can require various operations that in turn need flows of a certain (and at times great) complexity. This diagram shows an example of this type of facility and the loading movements that occur there.

Each flow added to the working system represents an additional cost when it comes to calculating the overall cost of the process within the warehouse. The greater the division of the unit loads, the greater the impact on costs. Picking operations account for the largest proportion of the total warehouse costs (up to more than 60%). This is why the design of these areas is of such importance.

In addition, the larger the warehouse, the further the handling machines and personnel have to travel and the greater the final cost of the operation. In centers with a great deal of movement, it is worth analyzing the possibility of introducing automation, so the product goes to the person rather than the person going to the product.

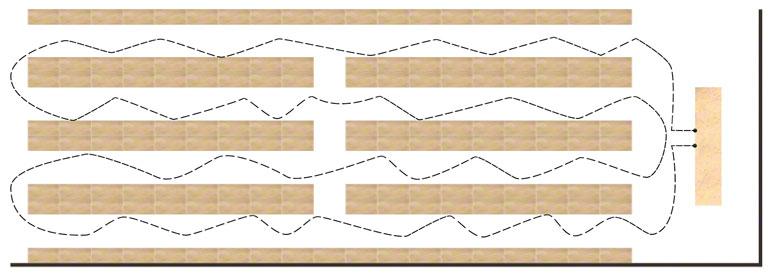

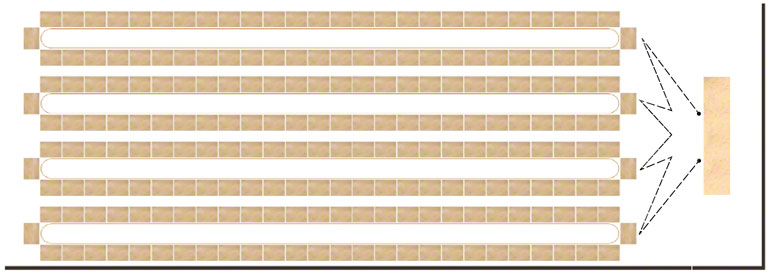

Picking installation with person-to-product operations.

Picking installation with product-to-person operations.

As is to be expected, the location of items depending on their consumption and volume is basic. The closer the high demand or large goods are to the loading and unloading docks, the lower the handling costs.

A good example is a warehouse where loose units are directly prepared. As explained in the discussion on unit loads, a single pallet can contain hundreds of sales units. Therefore. by moving these in a single operation it is possible to avoid the hundreds of movements that would otherwise be required to prepare each individual loose item.

All operations need a person, a machine, or both, to be performed. Therefore, it is vital to ensure that a single operator performs the greatest number of actions in a given time, or what boils down to, taking the shortest possible time for each operation. This applies to all activities in the warehouse. However, applying this principle is particularly important for picking, since this involves more movements than any other operation.

Product rotation: A-B-C

Miniload warehouse for hardware, industrial, DIY and construction supplies.

Another decisive factor that influences the speed and cost of operations is demand for the product or good. This is why items in most demand must be close to the loading and unloading docks. To this end, the concept of rotation is used. Products are classified as described below, according to their consumption:

A. High rotation: Units enter and exit continuously. These items are in high demand.

B. Medium rotation: Units enter and exit in smaller volumes than in A.

C. Low rotation: These are the items that spend the most time in the warehouse, and are in low demand.

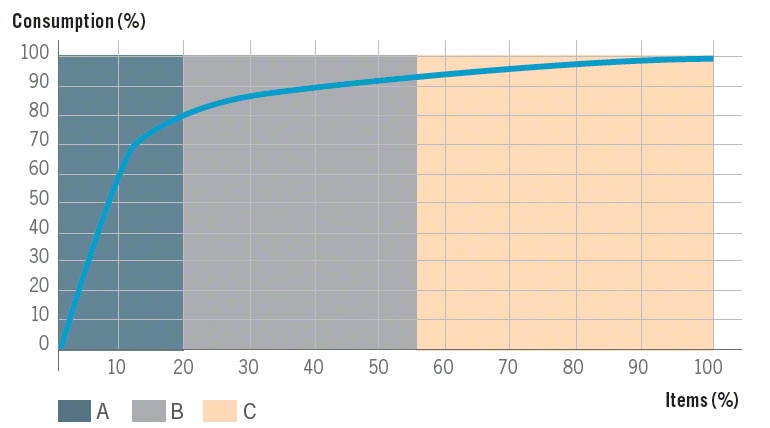

In most warehouses, the 80/20 rule or Pareto Chart applies. According to this rule, 80% of sales can be attributed to 20% of the products, while the remaining 20% of sales come from the remaining 80% of products.

Graphic representation of a Pareto chart.

Obviously, the flow of materials has to be treated differently according to the rotation in question ( A, B, or C). Below it illustrates two examples of possible criteria to apply:

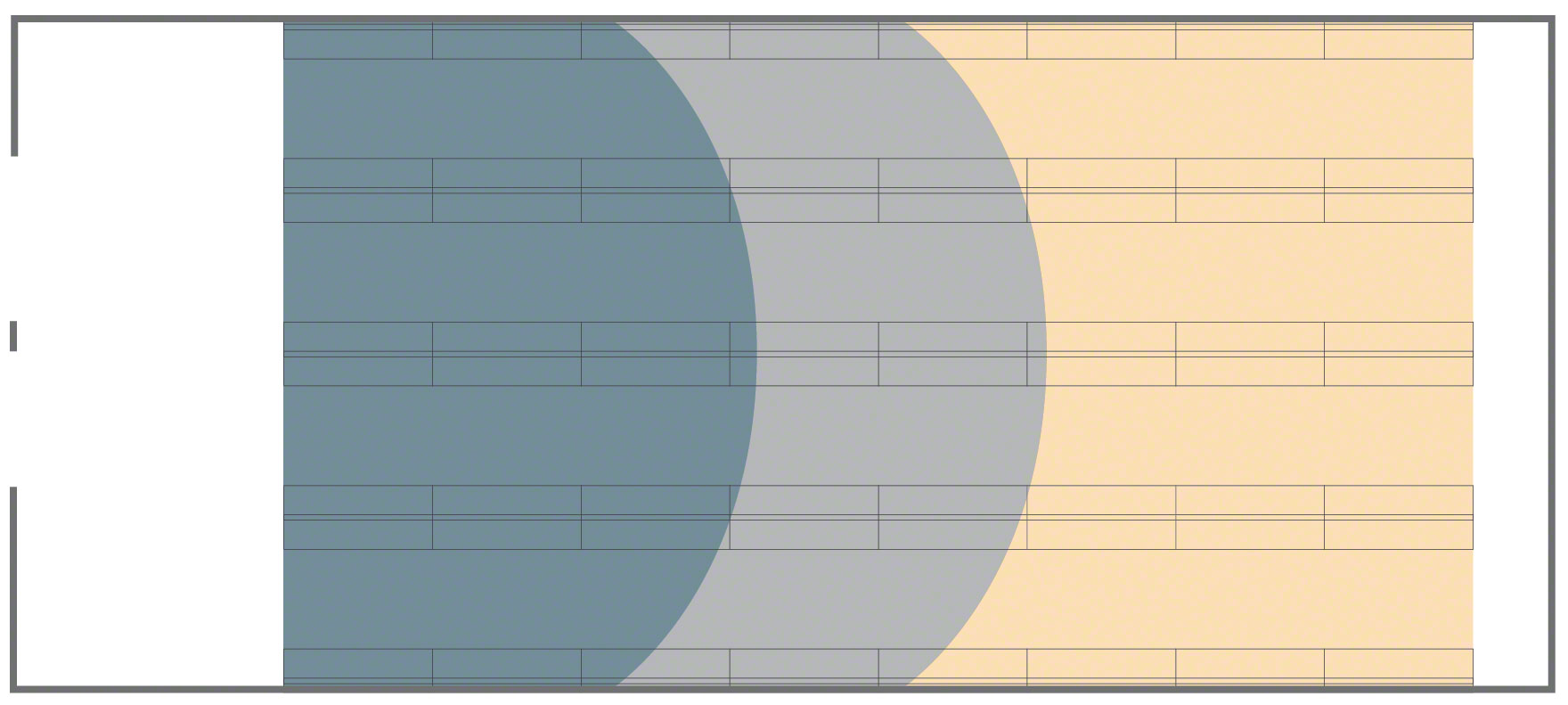

Product distribution throughout the warehouse according to rotation.

Distribution inside a rack (this normally applies to picking).

In the first example, the “A” products have been positioned closest to the loading and unloading area.

In the second example, the “A” products have been positioned in the most ergonomic part of the rack.

To arrange a warehouse in the most logical manner, each individual case must be analyzed. There must also be an awareness that things may not be that simple, given that there are probably existing factors to be taken into account.

At times, to make the best possible use of the available space, it will be advisable to position products according to the storage systems used. However, in other situations, speed and the shortest possible time spent on operations will take precedence. Where feasible, a combination of both factors will be sought.

One example that demonstrates this is the standard combination of selective and drive-in pallet racking in a warehouse, where the drive-in system is used for high rotation products.

Conclusions about flows and rotation

Handling costs can be reduced and, therefore, the warehouse made more profitable, if products are arranged in the correct manner according to their consumption, with appropriate handling, the correct order of flows, and if intermediate process points are correctly located .

To ensure that a warehouse is optimized, it is essential to choose the appropriate storage equipment, both in terms of the type of system and forklift trucks or handling equipment used.

The various storage systems (selective, drive-in, flow racks, etc.), explained in other articles, have different features which make them ideal in different situations. Having a good warehouse management system (WMS) is vital for achieving the objectives set out in this section.