Conservas Cerqueira installs a new automated preserves warehouse in Rianxo

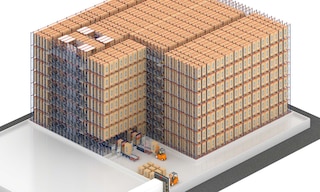

May 5, 2025Mecalux equips Conservas Cerqueira’s new warehouse in Rianxo with the Automated Pallet Shuttle System, optimizing packaging management and storage. Easy WMS software ensures traceability and operational efficiency in the plant, which is home to another automated raw material warehouse.