High-density storage and the Pallet Shuttle: a winning combination

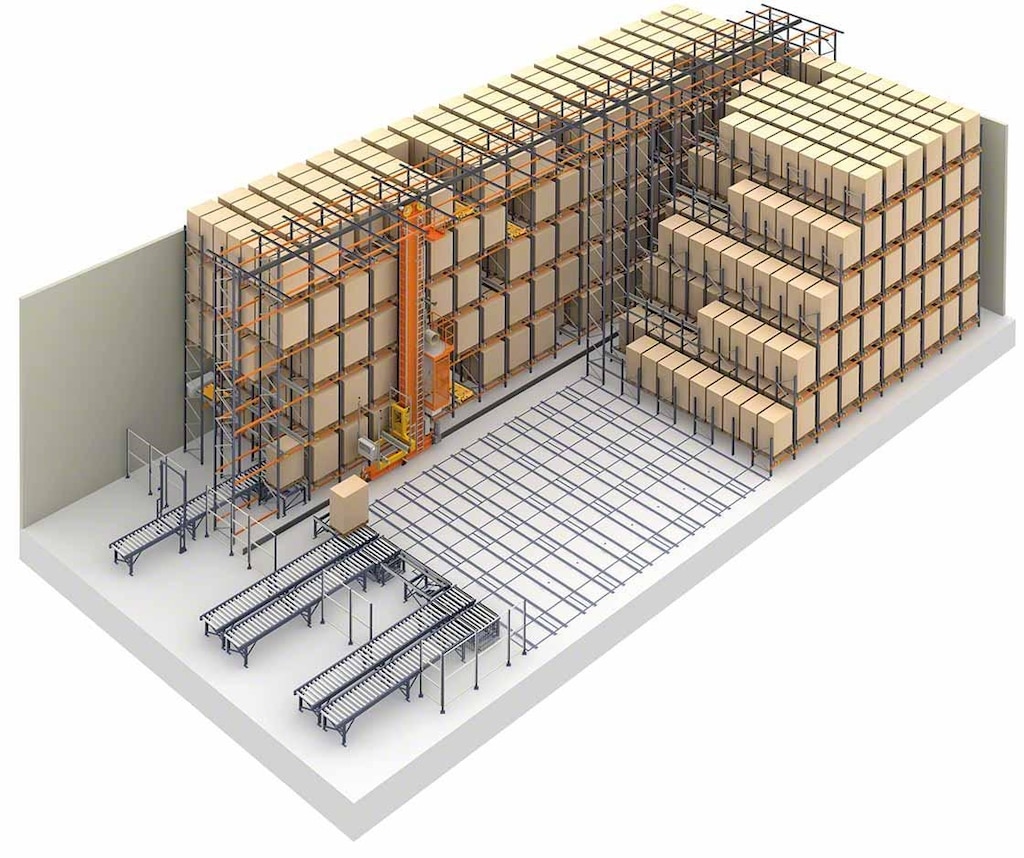

Two of the challenges facing more and more warehouses are the need for more storage capacity in the same floor space and the need for faster, more efficient movements of goods. High-density storage maximizes available space; but how do you achieve both objectives? One strategy has proved to be the first choice of many companies: partnering compact storage systems and the motorized shuttle called the Pallet Shuttle (semi-automatic or fully automated versions).

Advantages of the partnership between high-density racking and the Pallet Shuttle:

- High-density racking increases pallet storage capacity by working with channels depth-wise, eliminating aisle space.

- The installation of the Pallet Shuttle in conjunction with compact systems reduces the number of manual movements.

- Pallet Shuttles ensure rapid stock rotation according to established FIFO or LIFO criteria.

- The versatility of both systems makes them adaptable to all types of installations: refrigerated warehouses, dangerous goods warehouses, bulky goods warehouses etc.

Examples of installations combining high-density pallet racking storage and the Pallet Shuttle

The combination of high-density pallet racking with the Pallet Shuttle is designed for companies that carry a high volume of pallets per SKU and high loading and unloading activity. The following video shows how the system works:

Let's take a look at projects developed by Interlake Mecalux in which these systems are the focus of attention:

-The Hemosa warehouse, example of an automatic pallet shuttle and high-density pallet racking system

The company Hemosa, which supplies fresh meat and processed pork products, automated its temperature-controlled warehouse with the help of Mecalux. The project done up for Hemosa involved the installation of two types of high-density systems: carton flow shelving with rollers and high-density pallet racking combined with the Pallet Shuttle and a pallet stacker crane.

The automatic version of the Pallet Shuttle uses the stacker crane as its transport equipment along the center aisle. When the stacker crane halts at the indicated channel, the shuttle enters the storage lane in search of the specified pallet. All is controlled by the Easy WMS warehouse management system, which optimizes routes for maximum responsiveness and efficiency.

Thanks to the proper selection of the different types of racking along with the automatic systems and the Easy WMS software, the Hemosa warehouse has reached the desired capacity (more than 1,000 pallets) and has increased overall productivity.

-The versatility of the semi-automatic Pallet Shuttle as shown in the Didactic and Rockwool warehouses

Pallet Shuttle in the health sector: Didactic's project

The growth of Didactic, a French manufacturer of medical diagnostic instruments, put the operational capacity of its warehouse to the test. Previously equipped with Interlake Mecalux selective pallet racks, the installations needed an improvement in the available storage space, but without this redesign jeopardizing the high continuous inputs and outputs.

The solution provided by Mecalux for Didactic consisted in the installation of high-density racks run by the semi-automatic Pallet Shuttle system. Each block of racks’ has features adapted to the type of stock and to the rotation of stock it holds. The moving shuttle deposits or collects the pallets inside each channel. The operator controls the movements from a tablet, while remaining inside the forklift.

Rockwool, Pallet Shuttle system put to the test with bulky goods

The Rockwool project clearly demonstrates the versatility of compact type pallet racking in conjunction with the Pallet Shuttle. Rockwool is in the rock wool supply business, a material used to manufacture insulation in buildings.

The product stored by Rockwool is very bulky and is handled on 39″ x 95″ pallets weighing 440 lb. This not only makes it difficult to move loads, but also poses a challenge for the storage space in the facilities.

Mecalux ascertained a solution to adapt the high-density pallet racking systems by adjusting the width of the channels and by automating the movements inside the racks thanks to the semi-automatic Pallet Shuttle.

If you want to know if a high-density pallet storage/Pallet Shuttle combo is the ideal option for your warehouse, do not hesitate to contact us and an Interlake Mecalux expert will analyze your specific case.