IN-DEPTH ANALYSIS

By Marc Füchtenhans, Eric H. Grosse, and Christoph H. Glock

In their book Warehousing 5.0, professors Eric Grosse and Christoph Glock explore this concept, positioning warehouses as key drivers of competitive advantage and business success while highlighting their critical impact on supply chain efficiency. The book, with contributions from numerous researchers, summarizes the latest findings on the topic and serves as a guide for managers to transform their processes.

A considerable portion of greenhouse gas emissions from industrial facilities stems from heating, cooling, air conditioning, and lighting. In warehouses, lighting typically accounts for up to 65% of energy demand, significantly impacting operational costs and the facility’s carbon footprint.

The pressure to become more energy efficient and the increasing use of renewable energy sources have driven innovative solutions spanning smart homes, grids, cities, and factories. Light-emitting diodes (LEDs) have emerged as a popular and highly energy-efficient illumination source.

One characteristic of smart lighting systems (SLSs) is improved illumination quality and high energy efficiency achieved by the use of LED technology and intelligent light control solutions. Traditional systems typically consist of lighting fixtures controlled by switches. In contrast, SLSs use components such as motion or daylight sensors to adjust the intensity and even color of light based on environmental conditions and user requirements.

Characteristics of smart lighting systems

LED

These lights provide high energy efficiency, advanced control, short switching times, dimming techniques, a wide spectral power distribution, and high illumination intensity. LED luminaires have an efficiency of approximately 200 lm/W in industrial environments, while incandescent bulbs yield 15 lm/W and fluorescent lamps up to 100 lm/W. Further advantages are an exceptionally long lifespan (ranging from 50,000 to over 100,000 hours), robustness, stability, and flicker-free performance.

Sensor-based lighting

The objective is to minimize energy consumption and light pollution. To achieve this, the artificial light is only activated when motion is detected. In areas where natural light is available, sensors can be used to ensure that artificial illumination is only employed to complement daylight as needed. This approach has demonstrated significant energy savings, with reported values exceeding 40%.

Maintenance

Malfunctions in light management systems can have adverse effects on workflow efficiency and compromise safety standards. Therefore, intelligent maintenance analyses that include failure detection are essential.

Visible light communication

Technical advancements in LEDs have unlocked new possibilities for visible light communication (VLC). An extension of VLC technology is light-fidelity (Li-Fi). This encompasses a comprehensive wireless communication network that enables a secure, high-speed, bi-directional system, supporting user mobility and multi-user access.

Indoor positioning systems

LED-based communication may also work as a tool for indoor positioning systems (IPSs). Conventional IPSs rely on technologies such as RFID, ultra-wideband, and Wi-Fi, among others.

Human-centric lighting

This considers the visual, biological, and emotional effects of light on humans and the environment. Research has indicated that higher color temperatures can enhance attention, making it ideal for work environments. As a result, employees’ concentration after a break or during night shifts can be enhanced by a higher illumination level and cool, white light.

Applications in logistics

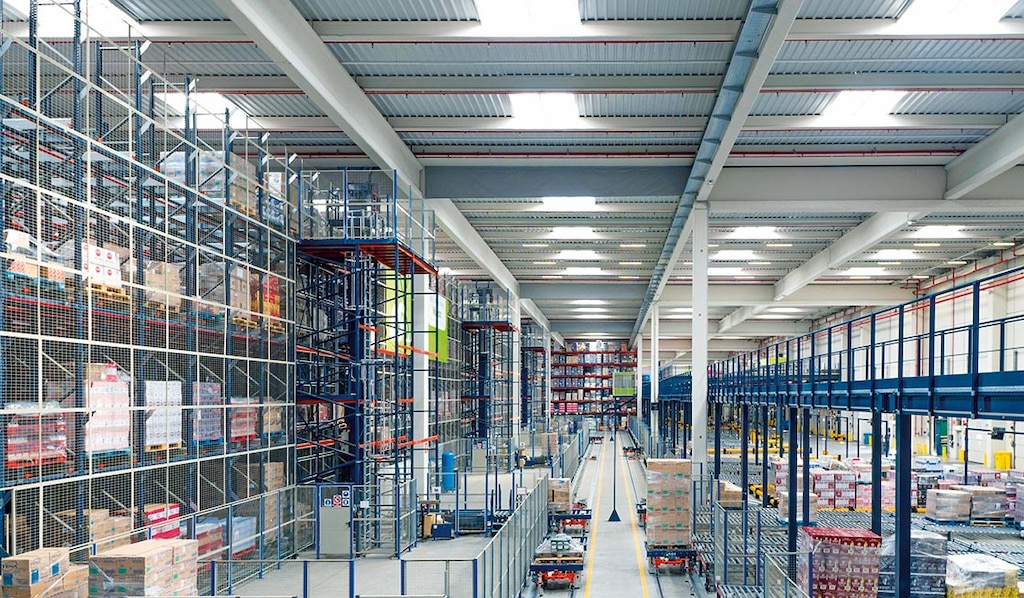

Order picking warehouses are an optimal use case for SLSs, as they often consist of large areas with zones that are either not constantly occupied or can benefit from the use of daylight. Illumination quality plays a crucial role because it impacts order picker performance. Poor visibility can lead to slower operations, a higher likelihood of errors, and increased risks of accidents.

It is worth noting that country-specific workplace regulations often set relatively low requirements. For instance, in Germany’s technical regulation, the minimum illumination for a warehouse ranges from 50 to 300 lux, depending on the work area. For facilities with reading tasks — such as the search-and-pick steps in order picking — only 200 lux are required, although an illumination level of three to four times that amount is needed to support clear reading.

Light quality plays a crucial role because it impacts order picker performance

The implementation of LED technology in warehouses can contribute to reduced energy consumption throughout the entire order picking process. Retrofitting conventional lighting with LEDs can achieve energy savings of over 50%. Depending on the initial setup, payback periods of less than three years are feasible.

In the context of order picking, where associates engage in physically and mentally demanding tasks, implementing SLSs could lead to a range of benefits for worker productivity and well-being. By incorporating controllable lighting technology, performance improvements can be achieved, as it generates feelings of autonomy and job satisfaction.

Case study in a warehouse

A case study and a simulation study were conducted to illustrate the possible effects of SLS implementations.

The case study data was collected from an Italian manufacturer of brass valves for the water and gas sectors. The company’s facility covers a total area of 46,285 ft², with 37,674 ft² designated as storage space. The warehouse has a rectangular layout, measuring 243' x 148', and features aisles of pallet racks with manual order picking operations. Windows allow the use of daylight in certain areas. Operations occur in two shifts spanning eight hours per day, five days a week.

Following a comprehensive energy audit, it was discovered that lighting accounted for up to 30% of the facility’s total energy consumption. Originally, the company utilized metal-halide lamps in the warehouse. Consequently, it made a strategic decision to enhance its lighting infrastructure to reduce energy consumption. It followed the guidelines of the EN 12464-1 standard, which specifies lighting requirements for indoor workplaces. A 1:1 replacement with new lamps was implemented with the goal of minimizing costs via retrofitting.

The implementation of LED technology in warehouses can contribute to reduced energy consumption throughout the entire order picking process

The company integrated SLS technology, consisting of daylight sensors and motion detectors. This integration allowed for dynamic control of the lighting levels, taking into consideration the influence of natural light. As a result, the system could adapt the illumination intensity in each aisle based on its usage.

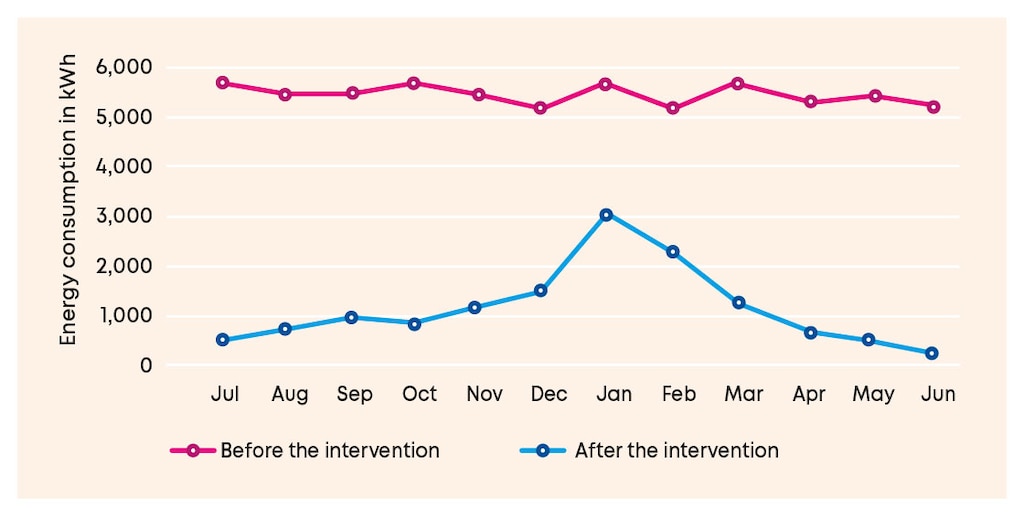

After the installation, data were collected over 12 months. The results were remarkable, with lighting consumption in the warehouse decreasing by approximately 80%. Notably, the facility benefited considerably from daylight sensing, leading to greater savings during summer periods.

Lighting energy consumption (kWh) in the warehouse (adapted from Füchtenhans et al., 2023)

Extracted from the book Warehousing 5.0 by Christoph H. Glock and Eric H. Grosse

The installation of the SLS had a positive effect on lighting quality as well, with an increase of around 50 lux at the floor level in the warehouse aisles. The total cost of modifying the facility amounted to $19,000, equivalent to $2,700 per kW of installed lighting power. With such substantial energy savings and enhanced illumination quality, the investment demonstrated a payback period of 1.9 years.

Strategies for energy and cost savings

To gain further insights into how SLSs influence facility performance, we also developed a simulation model of a manual order picking warehouse. Our model considered various aspects of facility design and operations, such as size, demand patterns, the number of order pickers, storage assignments, and batching policies. We implemented four strategies, representing varying degrees of smart lighting technologies:

- The first two systems fully illuminated all aisles during operations.

- The third reduced the light intensity in picking aisles that were not in use at the time.

- The fourth incorporated fully illuminated activity zones and reduced light outside of these areas.

The simulation results demonstrated that SLSs can decrease energy consumption by up to 87% compared to conventional full-time facility illumination. Regarding potential return periods for SLSs in warehouses, our simulation results, case study data, and expert workshop discussions led to the following conclusions:

- For a warehouse with an area of 80,720 ft² and an annual lighting duration of 7,000 hours, the average total yearly energy consumption using fluorescent lamps is approximately 1,792 MWh, with a cost of around $358,000 a year (based on an energy price of 0.20 kWh).

- By retrofitting those lamps with LED bulbs, this is reduced to 1,174 MWh, resulting in electricity costs of $234,500 per year.

- Integrating daylight sensors (assuming 4.4 hours of sunshine per day) and a control system allowing for dimmable illumination levels can further lower energy consumption to 987 MWh, $197,000 per year.

- Considering the average lifetimes — 15,000 hours for fluorescent lamps and 50,000 hours for LEDs — the maintenance cost of the former system would accumulate to $640,000 over 10 years.

- The retrofit and/or redesign required to implement the LED lighting system is estimated to be $1.1 million, but maintenance costs are eliminated in this scenario.

Based on these assumptions, the return period for a lighting system without any sunshine hours is 5.9 years. However, if the system were equipped with daylight sensors accounting for 4.4 hours of daily sunshine, that period would decrease to 4.9 years.