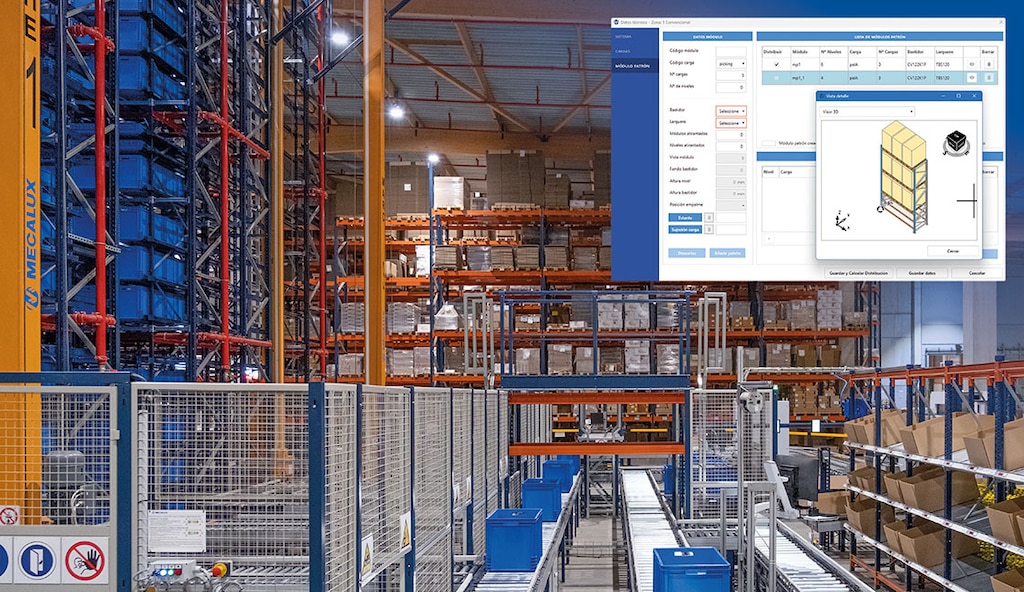

A well-designed warehouse streamlines stock management, order processing, and customer service. With the right storage systems, products are kept in optimal conditions and can be located quickly and easily. Good design also increases productivity and cuts costs by maximizing available space and accommodating a larger number of SKUs.

When planning a warehouse, one of Interlake Mecalux’s top priorities is to ensure an efficient flow of goods. To achieve this, it supports companies throughout the entire process of designing a solution that aligns with both current and future needs.

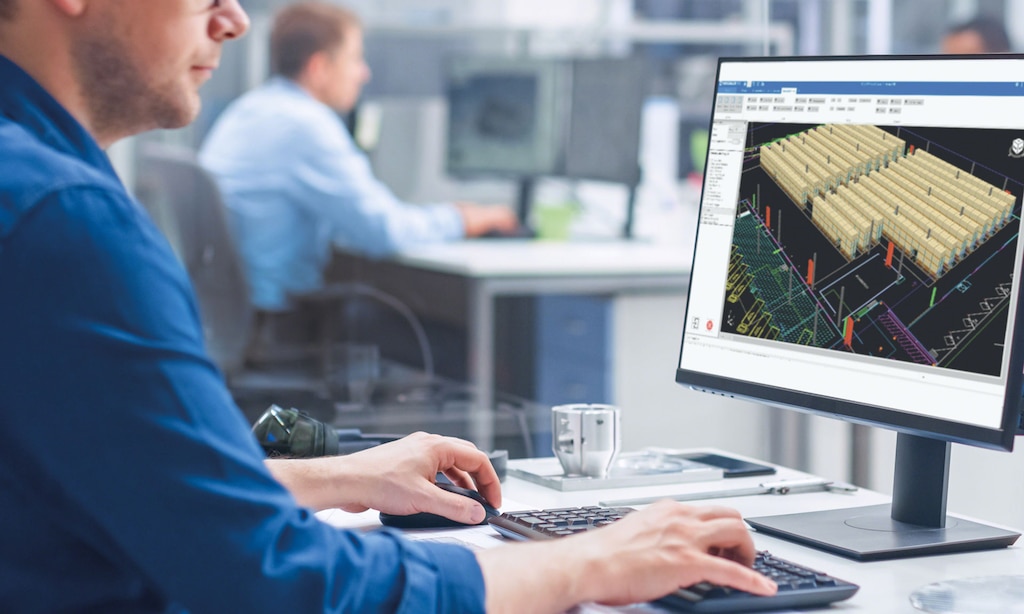

Software for warehouse system design

Interlake Mecalux uses proprietary software to configure storage solutions adapted to each client’s requirements. Developed in-house, this tool standardizes processes and applies the latest technological advances to engineering design. It automates tasks such as structural calculations, plan drafting, and bill of materials generation — streamlining the work of draftspeople, technical teams, sales departments, and distributors alike. This commitment to digitalization has significantly improved both the efficiency and consistency of project development over time.

Interlake Mecalux’s software transforms data into safe, efficient technical solutions tailored to any environment

The following are some of the system’s features:

- Space optimization. Defines the ideal dimensions and layout of storage systems based on available surface area, building features (e.g., columns or roofs), facility height, and expected workflows.

- Component selection. Chooses the most suitable materials, finishes, and accessories according to the type of load, environmental conditions, and applicable regulations.

- Mechanical compatibility. Adapts the warehouse layout to the handling equipment used in each case, ensuring proper movement and operation.

- Flexible design. Enables the solution to be adjusted based on product weight, volume, turnover, temperature requirements, and other characteristics.

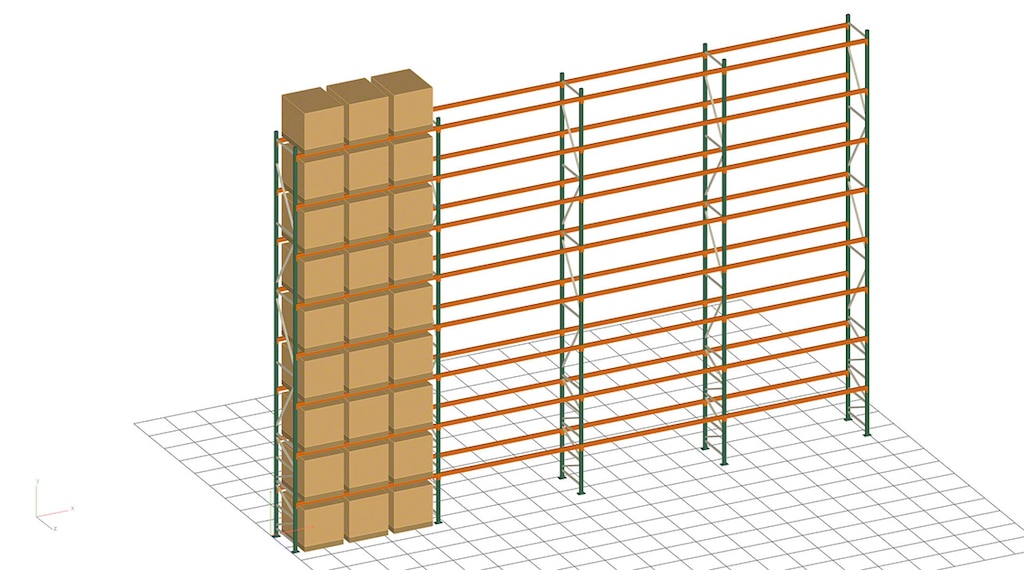

- Technical representation. Generates detailed 2D and 3D plans and documentation, including load reports and visual renderings to facilitate client validation.

Interlake Mecalux generates technical documents and detailed 2D and 3D layouts

The Interlake Mecalux application connects with the company’s internal platforms (e.g., ERP and CRM) to enable data exchange between the planning, purchasing, and engineering departments. This integration provides access to key information such as the item master and sales processes, maintaining consistency throughout the project and supporting informed decision-making.

The program selects materials, refines the design, and generates 3D layouts ready for client approval

The software verifies the structural strength of proposed systems based on regional regulations (for example, seismic zone requirements) and the client’s intended use.

With this digital tool, Interlake Mecalux designs functional storage systems that maximize capacity while meeting the highest safety standards.

Technology applied to warehousing: Key benefits

Interlake Mecalux’s design software offers numerous advantages for businesses that rely on its storage solutions. These are some of the ways it benefits clients:

- Tailored solution. The tool adapts to specific company characteristics: available space, type of goods, operating processes, and future needs. The result is a storage system that aligns perfectly with the organization’s operations and goals.

- Visibility and control before implementation. 3D simulations and layouts provide an accurate preview of the final storage system, making it easier to understand and adjust the design as needed.

- Time and cost savings. Integrating with ERP and CRM software streamlines the project development process, reducing the risk of calculation errors or mid-project changes. This approach saves both time and resources.

- Operational improvement. The system analyzes multiple variables to propose the most efficient configuration. It maximizes storage capacity, minimizes cost, and enhances daily operational flow.

- Safety and regulatory compliance. From the design phase, the software ensures that every solution complies with current regulations and standards, protecting both goods and personnel.

Interlake Mecalux engineering: The calculation engine

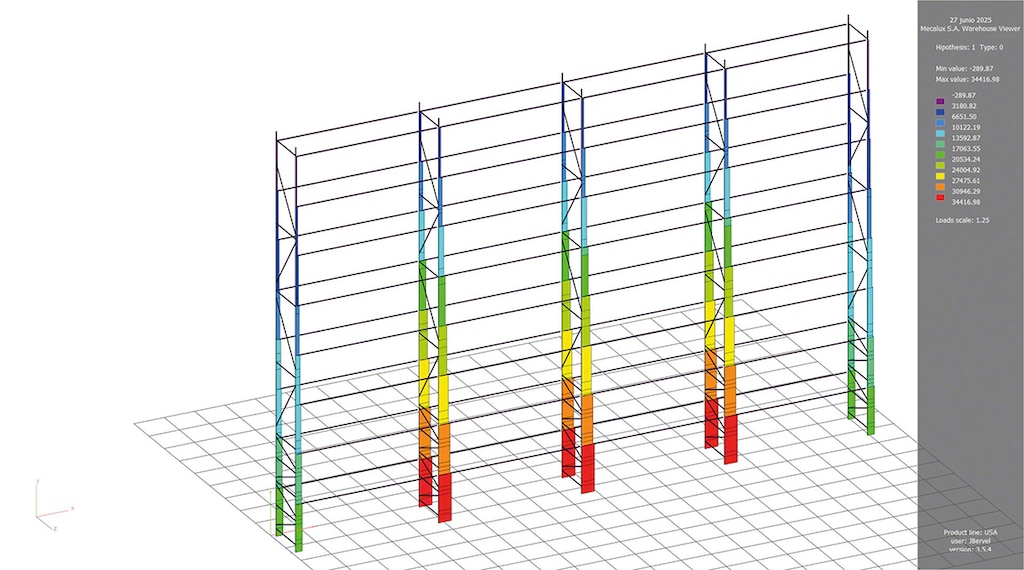

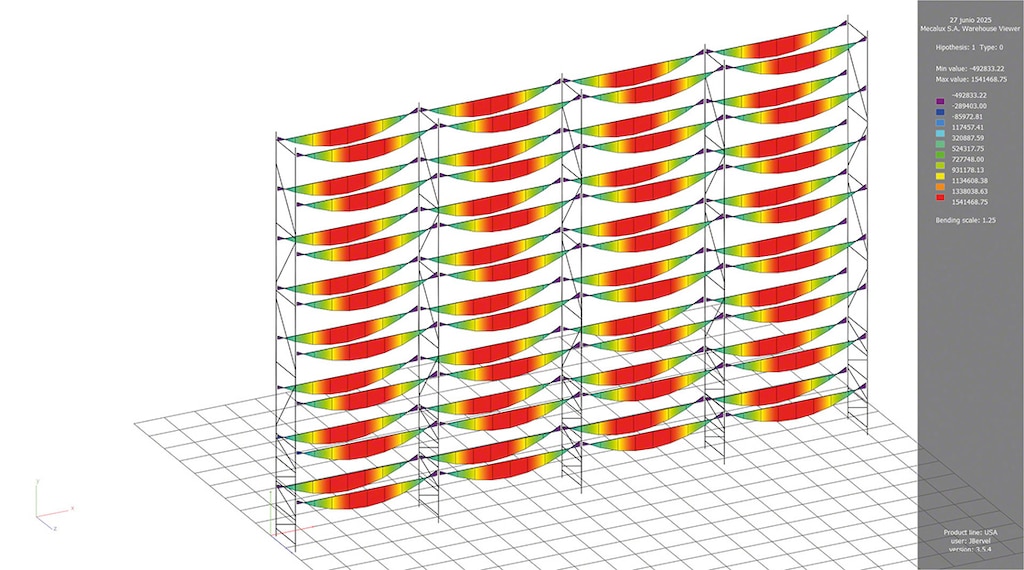

At the core of Interlake Mecalux’s design software lies its calculation engine. This advanced tool uses evolutionary algorithms to identify the most efficient, safe, and cost-effective storage solution.

The engine swiftly processes a wide range of parameters, including load capacities, material strength, system performance under various conditions, and compliance with technical and regulatory requirements.

Compression force distribution in the posts of a storage rack

Bending moment distribution in storage system beams

By applying evolutionary algorithms, the calculation engine explores multiple possible configurations. It then iteratively selects those that best meet design, structural efficiency, and sustainability criteria.

The result is a fully validated technical proposal ready for real-world implementation. The solution uses fewer materials without compromising structural integrity, reducing both resource consumption and the environmental footprint of each system. The engine also generates supporting documentation, such as structural calculation reports, for the sales team or end customer.

Rendering showing the racking system with the selected setup

The calculation engine provides an optimal solution for the present as well as excellent adaptability to future needs (e.g., changes in regulations or logistics requirements). Integrated data analysis tools further drive innovation. They enable the engine to uncover usage patterns, identify areas for improvement, and support the development of new products by the Mecalux Group’s R&D team.