Normagrup: automation shines a light on logistics

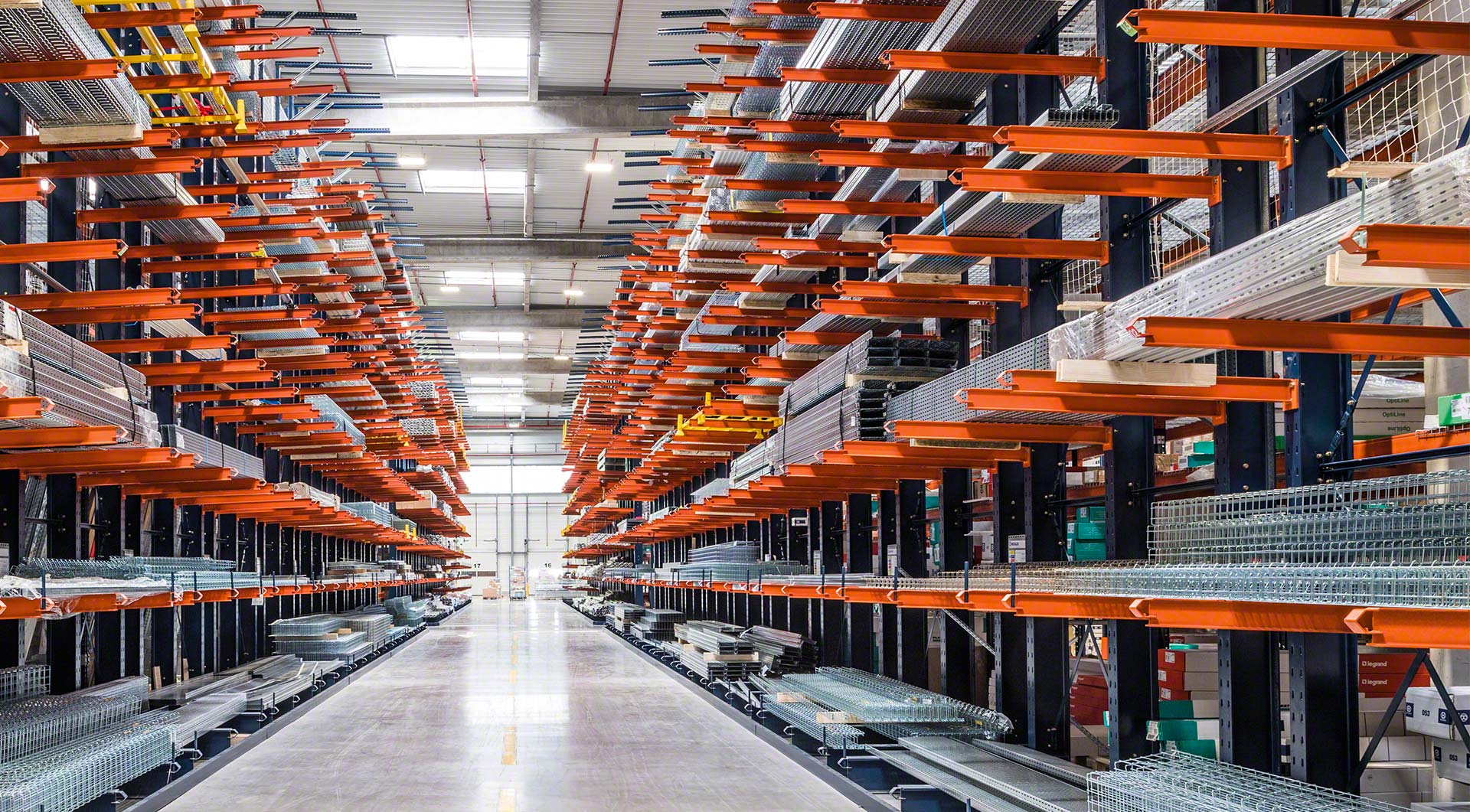

Normagrup has demonstrated its commitment to innovation and state-of-the-art technology with this AS/RS for boxes and the software from Mecalux, a system that has improved management of raw materials, optimised space, and increased the flow of movements.