Button manufacturer Luca Cuccolini has installed an automated warehouse for boxes

Easy WMS is integrated with the Sage 200c ERP, transferring information to ensure more efficient operations

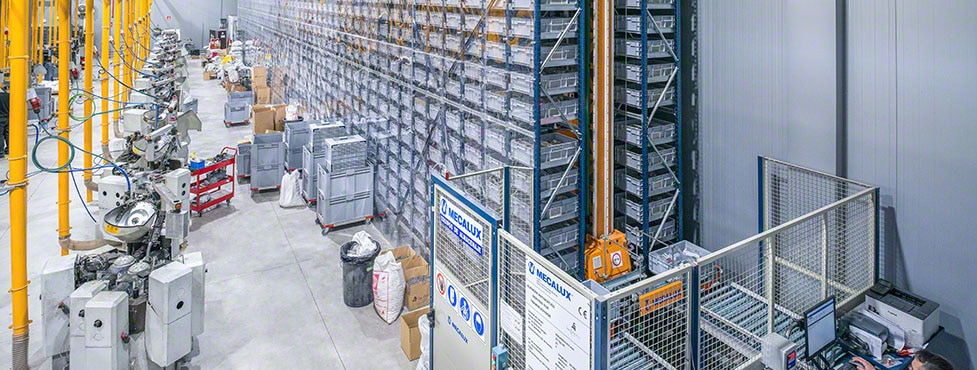

Luca Cuccolini, a renowned button manufacturer with a history of over 50 years, has updated its logistics with the installation of an automated warehouse for boxes at its center in Illescas (Toledo, Spain). With capacity for 2,640 boxes in just 646 ft2 of surface area, the new installation manages the millions of buttons the company produces every year. In turn, the automation and supervision provided by Interlake Mecalux’s Easy WMS have enabled the firm to streamline order preparation and increase productivity throughout its supply chain, meeting the needs of the major fashion brands.

Mad about buttons

Founded in 1969, Luca Cuccolini is a family business with years of experience in manufacturing buttons, accessories, and appliqués for clothing items such as patches, broaches, ribbons, and the like.

With a staff of over 40 employees, Luca Cuccolini exports its all-natural, chemical-free, eco-friendly products to five continents. In addition to its presence across Spain, the company has sales offices in France, Portugal, the UK, Italy, the US, and Turkey. Luca Cuccolini has a production center in the town of Illescas in central Spain.

There, it manufactures millions of buttons annually for a multitude of garments sold all over the world. Just alongside the production lines, the company has a storage area where it manages raw materials and finished products.

The firm competes with many button manufacturers, mainly in Italy, a country with a button-making tradition spanning over 300 years, and in China. Nevertheless, in recent years, it has managed to position itself as an international reference in the world of fashion and design. Luca Cuccolini has achieved this through its clear commitment to R&D, which has enabled it to create original, modern buttons that shine on the most exclusive runways and in the store windows of hundreds of fashion brands.

Progress in step with automation

The company set out to modernize its logistics operations with the aim of boosting its international expansion and guaranteeing the uninterrupted supply of buttons to all its customers.

Until recently, the firm had always worked with traditional storage systems. However, it realized that automation was the solution that best suited its business.

On the one hand, this optimizes storage space. Luca Cuccolini’s production plant and installation are located in an industrial park with defined dimensions and no room to grow. On the other hand, automation is synonymous with productivity, on account of smoother operations. According to company General Manager Luca Cuccolini, “We are convinced that automation helps us to manage warehouse stock accurately, in addition to streamlining storage and picking tasks.”

The firm decided to install an automated warehouse for boxes by Interlake Mecalux, since, there, it would be able to store its multiple small SKUs. Luca Cuccolini manages small items, for the most part. It does, however, receive several raw materials on pallets, which are temporarily deposited on the racks until they are needed on the production lines.

One particular feature of the automated installation for boxes is its profitability, as it ensures high throughput and capacity in a limited space. In the case of Luca Cuccolini, it can accommodate 2,640 boxes, each containing multiple items and SKUs, in an area of barely 646 ft2. The warehouse comprises a 98-foot-long single aisle. It is equipped with single-deep racks measuring 23' high and with 21 storage levels on both sides.

High performance in the front

Two of this installation’s most important operations — raw material inflows and outflows and order preparation and consolidation — take place in the front of the facility, at the end of the racking.

Operators remain at a workstation, specifically set up right at the front of the warehouse, waiting for the goods to be brought to them automatically. This work system, known as product-to-person, eliminates operator travel and, as a result, raises productivity, enabling one employee to prepare many orders.

The workstation is fitted with computer equipment connected to Easy WMS, the warehouse management system by Mecalux, so that operators can see which tasks they need to perform.

At the entry points, boxes containing goods (whether from production or sent by suppliers) must go through a checkpoint. There, their weight and dimensions are examined to verify that they meet the requirements established for placement in the installation.

Control and agility

The warehouse is equipped with Easy WMS, which manages all movements and operations carried out in the automated installation.

Easy WMS communicates continuously and bidirectionally with the Sage 200c ERP at Luca Cuccolini, transferring data and information to make the warehouse function more efficiently. The company’s General Manager explains, “Integrating the installation with production was a priority. By connecting the WMS with the ERP, we ensure that the production lines are supplied with raw materials in a timely manner and whenever they are needed.”

The WMS tracks goods throughout the warehouse. Once the products have been received and have gone through the checkpoint, the WMS assigns them a location based on whether they are raw materials or finished products and according to their demand level.

Easy WMS also helps to make order prep much simpler and faster. Via the monitor located at their workstations, operators can consult which items they need to extract, how many, and where to deposit them.

Innovation and automation

Luca Cuccolini is noted for modernizing its processes and operations for the purpose of strengthening its growth. This strategy has yielded stunning results: it has become a leading company in Spain and in its sector. Moreover, it has become internationalized, competing with major button manufacturers worldwide.

The new automated installation for boxes is intended to bolster Luca Cuccolini’s constant growth. This warehouse operates continuously, storing raw materials and finished goods in addition to supplying the production lines as necessary.

All aspects have been taken into account, down to the last detail: the available surface area was leveraged to achieve the maximum storage capacity (up to 2,640 boxes in merely 646 ft2). Likewise, Easy WMS was implemented to get the most out of operations and gain flexibility.

Luca Cuccolini - General Manager at Luca Cuccolini

“We are extremely satisfied with this new installation because it has helped us to revamp and improve our logistics systems. Automation has given us greater control and speed in storage and order prep tasks. On a final note, the Easy WMS warehouse management system was crucial for optimizing operations and carrying them out in a completely safe manner.”

Advantages for Luca Cuccolini

- Maximum use of surface area: in just 646 ft2, Luca Cuccolini has an automated solution that can manage 2,640 boxes.

- High productivity: the automated installation for boxes offers high throughput in goods entry and dispatch processes.

- Quick order prep: operators do not need to move, as the stacker crane is charged with bringing the products to the pick station, thereby streamlining preparation.

| Automated installation for boxes | |

|---|---|

| Storage capacity: | 2,640 boxes |

| Box size: | 16" x 24" |

| Max. box weight: | 55 lb |

| Racking height: | 23' |

| Racking length: | 98' |

Gallery

Luca Cuccolini's automated warehouse for boxes in Illescas, Spain

Ask an expert