The European leader in online sales to the general public, vente-privee, increases the efficiency of its Rhône-Alpes (France) distribution centre

Improved logistics efficiency at vente-privee with the high-density Pallet Shuttle system

Interlake Mecalux has supplied the Pallet Shuttle system in the distribution center vente-privee owns in the Rhône-Alpes region (France). Via this solution, the company who specializes in the online sale of brand name products fully uses the available surface and has minimized the movements of the operators inside.

About vente-privee: its needs

vente-privee is a French e-commerce company with a broad selection of brand name products in fashion, toys, watches, decor and household items, technology, recreation, cuisine, etc. Founded in 2001, it currently has more than 30 million users throughout Europe and the U.S.

The enterprise started out with a warehouse equipped with selective pallet racks, mainly used to prepare online orders.

However, in the last few years it was forced to enlarge storage capacity to deal with business growth and the expansion resulting from its highly successful flash sales offers: special promotions with time-limited discounts until stock runs out. This type of marketing involves a huge challenge from a logistics point of view and requires an excellent organization to guarantee the desired service.

To this effect, and in order to restructure all the operations of the distribution center, vente-privee turned to Interlake Mecalux for advice.

The solution by Interlake Mecalux

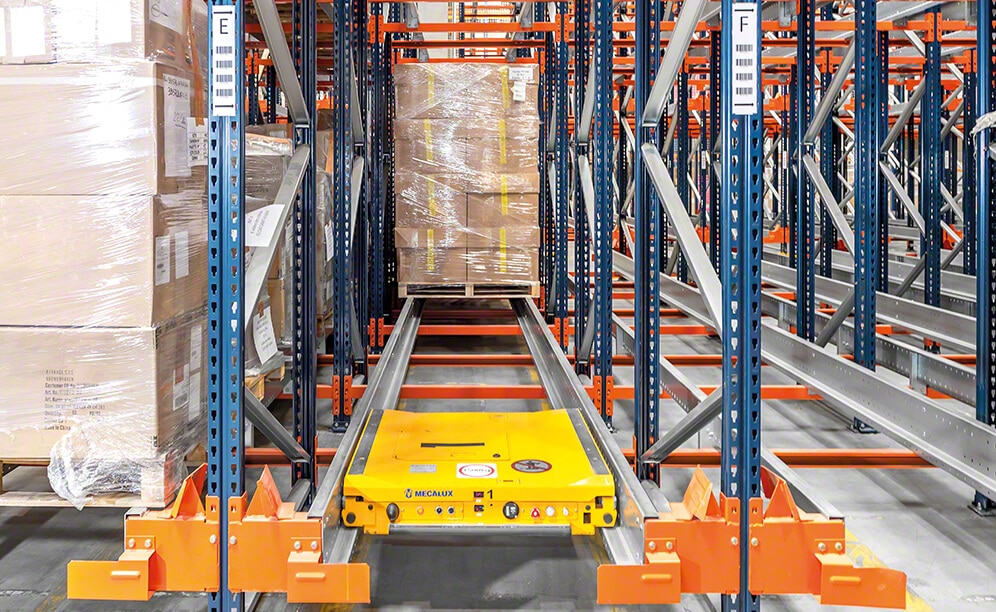

Interlake Mecalux installed two blocks of high-density racks served by Pallet Shuttles.

The two blocks, measuring 77' long with four-levels reaching 33' in height, manage the goods in various ways depending on the logistics needs of vente-privee:

- One block with a single access aisle where the LIFO (last in, first out) criterion is applied, i.e., the last pallet in is the first one out. Reserve consumer goods are housed here.

- One block that follows the FIFO (first in, first out) criterion for palletized consumer goods. It features a loading aisle and another for unloading to avoid interference between the two operations.

To function, the operators place the motorized shuttle into the corresponding channel, they deposit pallets into the first position of the racks and the Pallet Shuttle transfers them to the first open location. The same operation is performed in reverse order to remove the goods.

Control tablet

The installation is equipped with control tablets which are tasked with sending orders to all the Pallet Shuttles of the warehouse according to prioritized protocols.

Operators, via the tablet, can select the shuttle they are going to work with, how many pallets must be inserted or extracted, manage authorized personnel or automatically take inventory. The number of shuttles that the tablet controls can be expanded with the growing needs of the warehouse.

Advantages for vente-privee

- Top throughput: the Pallet Shuttle system guarantees maximum speed and safety in goods management, minimizing operator maneuvers.

- Space optimization: the racks make full use of the available space to achieve a storage capacity of more than 1,200 pallets.

- Dynamic operations: the optimal organization of the warehouse operations results in the faster picking of online orders.

| Distribution centre vente-privee | |

|---|---|

| Storage capacity: | 1,276 pallets |

| Pallet size: | 32" x 48" x 79" |

| Max. pallet weight: | 1,100 lb |

| No. of channels: | 116 |

| Channel depth: | 31' |

| Rack height: | 33' |

Gallery

Mecalux has supplied the Pallet Shuttle system in the distribution centre vente-privee

Ask an expert