Slotting for WMS

The Slotting for WMS module calculates the ideal location taking into account the warehouse layout, movements, picking method, and equipment used

Ask Our Experts

Automate location management in your warehouse

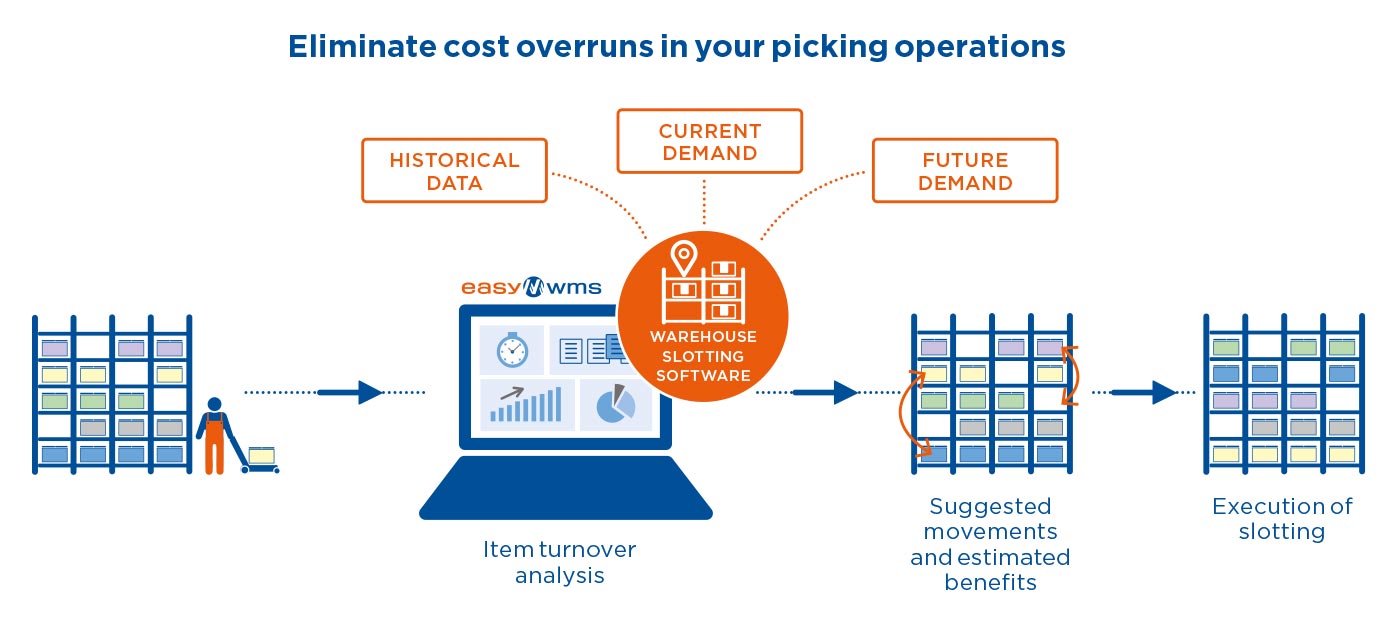

This software determines the optimal location for each SKU based on a set of rules and criteria predetermined by the logistics manager and an analysis of current, historical, and future demand for each product.

The module calculates the ideal location taking into account the warehouse layout, movements, picking method, and equipment used. In doing so, it recommends classification of products according to sales forecasts or demand analysis. This way, SKUs that are usually ordered together are slotted close to each other, optimizing operator pick paths.

This is especially useful in the e-commerce and retail industries and in highly seasonal businesses with promotional campaigns, i.e., Black Friday. Slotting for WMS analyzes market trends and suggests the redistribution of warehouse locations to facilitate more productive picking and minimize manual errors. Additionally, the module can be configured to make automatic recommendations regularly and even propose suggestions only when a certain benefit threshold is exceeded.

Optimize the location management in your warehouse

Benefits of Slotting for WMS

|

|---|

SLOTTING FOR WMS REDUCES TIME AND OPERATIONAL COSTS BY AUTOMATING LOCATION MANAGEMENT

Functions of Slotting for WMS

- Organization and recommendation of warehouse location changes.

- Analysis of turnover and demand (current and historical) for each SKU.

- Estimation of benefits based on slotting strategies.

- Automatic generation of stock relocation tasks for each SKU.

In-warehouse location management

Slotting for WMS, the advanced Easy WMS functionality, requires proper parameterization of the module and of the warehouse management system using data on the operation of the warehouse, its layout, and the assignment of each SKU located in the facility.

The module optimizes location management by updating slotting in line with historical, current, and future demand for each product. The program suggests new locations constantly, prioritizing the movement of SKUs that have the highest turnover at any given time.

Directly connected to operators via RF scanners, Slotting for WMS automatically generates goods redistribution tasks in the facility. The software designates an empty location as a slotting buffer, i.e., a space to temporarily store the goods before placing them in their new optimized locations.