Warehouse pallet rack components and parts names

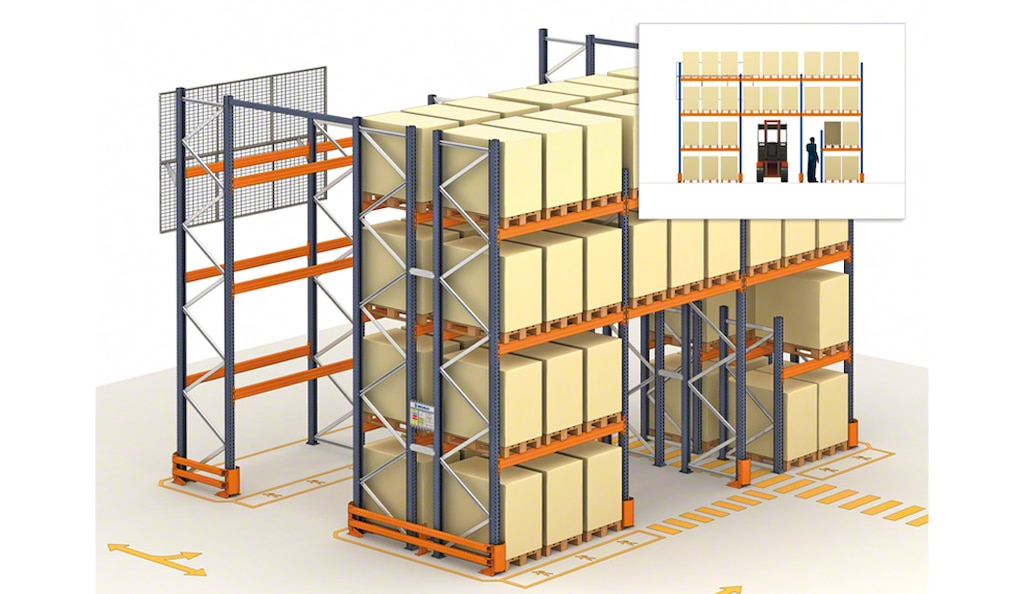

Pallet rack parts comprise the multiple components that make up the structure of the racking and ensure the proper storage of the loads it holds. In this post, we take a look at the main warehouse racking parts and their function. For reference, we’ll use selective pallet racking due to its extensive variety of components. Nevertheless, structural elements such as beams, frames, and crossbars are common to all metal pallet racks.

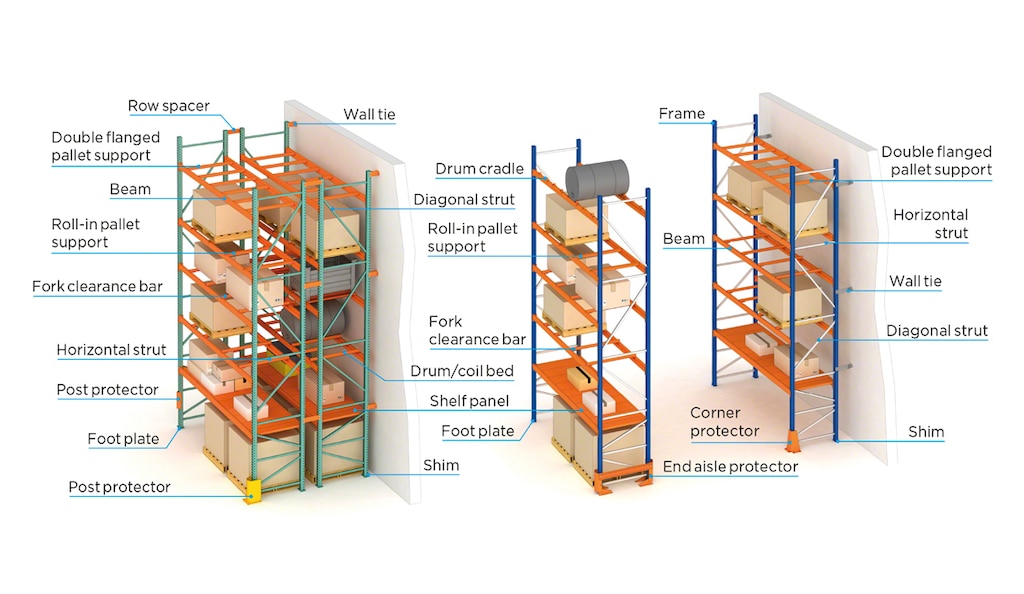

Industrial rack components can be broken down into fastening elements (posts, beams, and frames) and accessories. These accessories, meanwhile, can be classified as those that adapt the structure to the load (special shelf panels, drum/coil beds) or those that reinforce its safety (fall protection netting, locking devices) in addition to that of the facility (shims, sign holders). The following graphic illustrates all the parts that make up a pallet rack: Further below, we explain each of the components in detail.

Basic parts of a pallet rack

These are the main pallet racking parts names and their functions:

Posts

Metal parts that form the vertical structure of the racking frame. There are many models of posts available that adapt to the various types of loads, weights, and sizes. Each post has a footplate to affix the structure to the warehouse floor.

Diagonal struts

Metal posts that join the posts diagonally to constitute the structure of the frame. Diagonal struts reinforce the load capacity of the posts and, thus, guarantee the stability of the pallet rack.

Frames

Metal structure that serves as the vertical support of the rack. They are formed by two posts and the diagonal struts, footplates, and corresponding accessories.

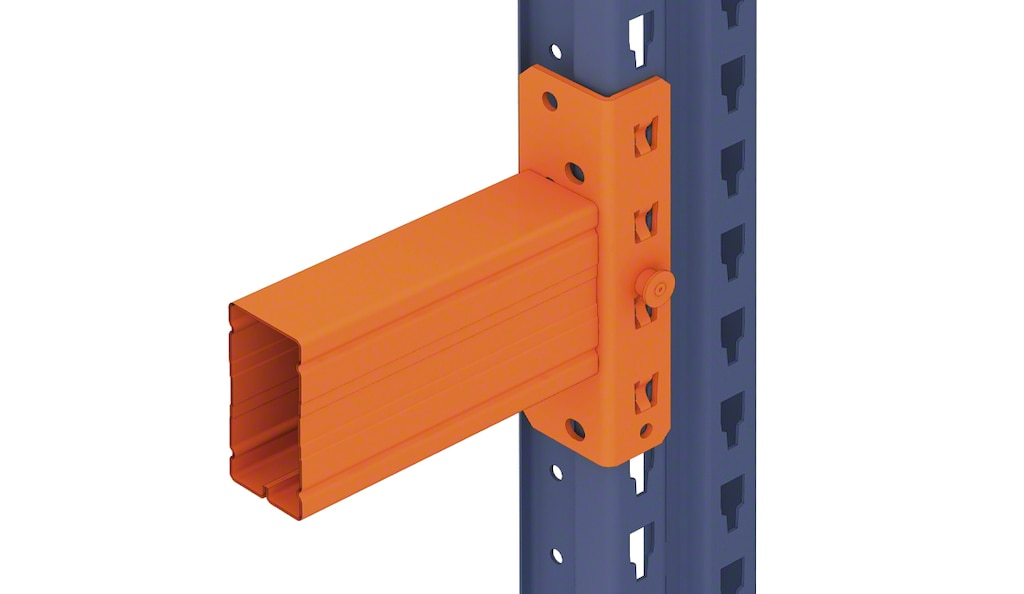

Beams

Horizontal metal profiles that are directly attached to the frames. They are used to hold the pallets or support the shelving panels on which the goods are deposited. In racking structures for palletized loads, pallet stops can also be incorporated to prevent the goods from coming loose from the structure.

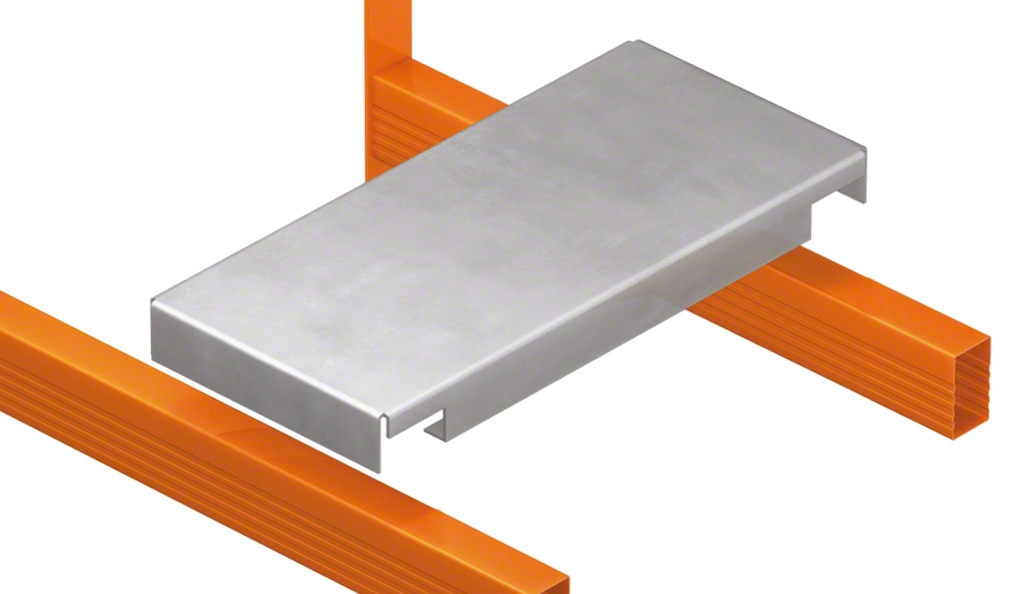

Shelf panels

Shelf panels are the pallet rack components that are supported by the beams in order to hold the load. Depending on the type of merchandise stored, these shelves can be grated, wooden, or galvanized metal.

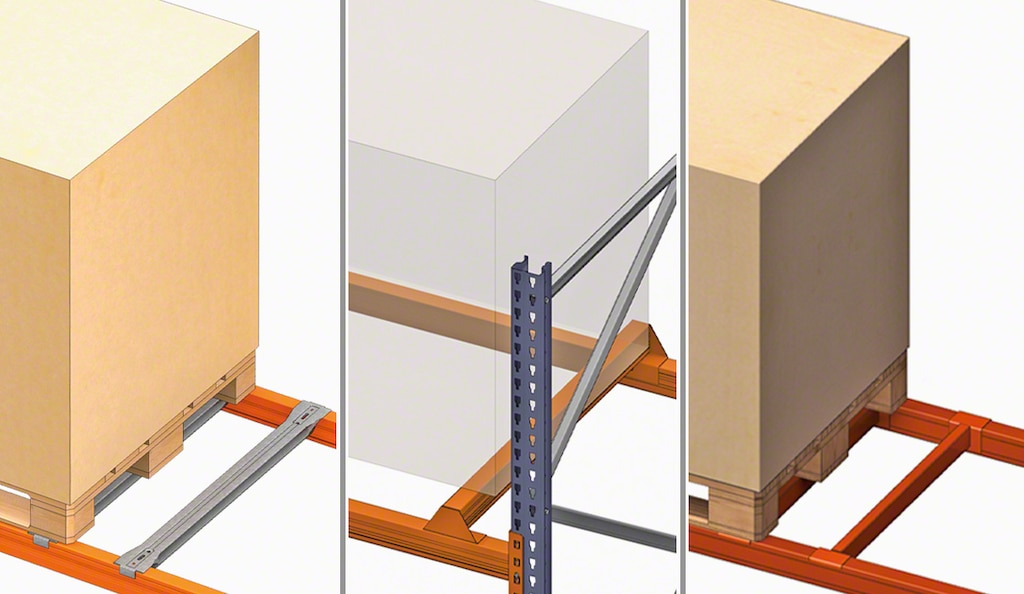

Crossbars

Metal profiles placed perpendicularly to the beam to reinforce the stability of the loads. This part of the racking prevents pallets from accidentally falling (and potentially breaking). It also facilitates the insertion of pallets on the wide side.

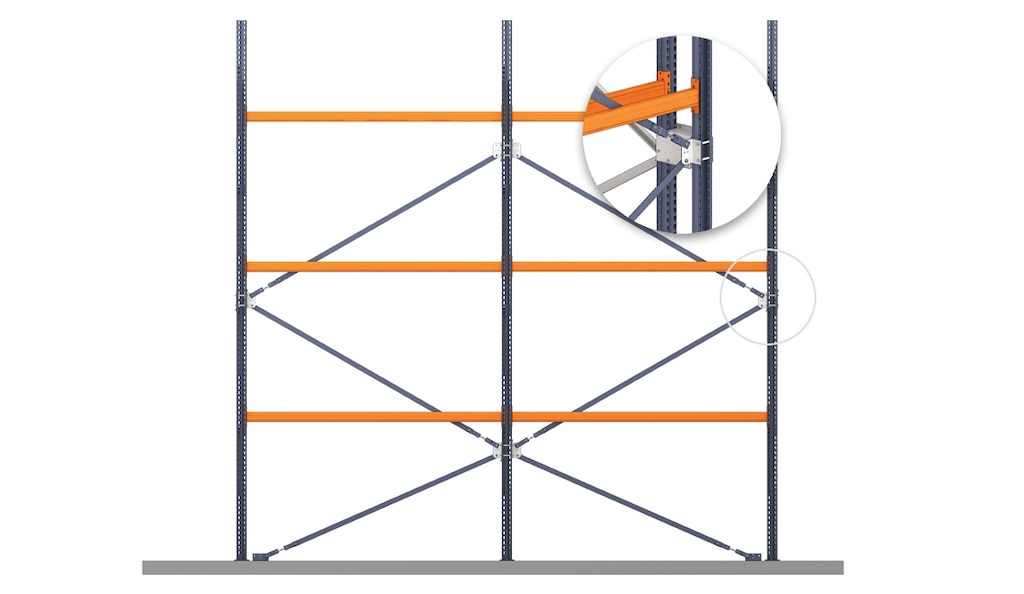

Bracing or cross bracing

Metal profiles affixed to the beams to strengthen the pallet rack’s load capacity. Each profile has a tensioner that provides it with the necessary stiffness.

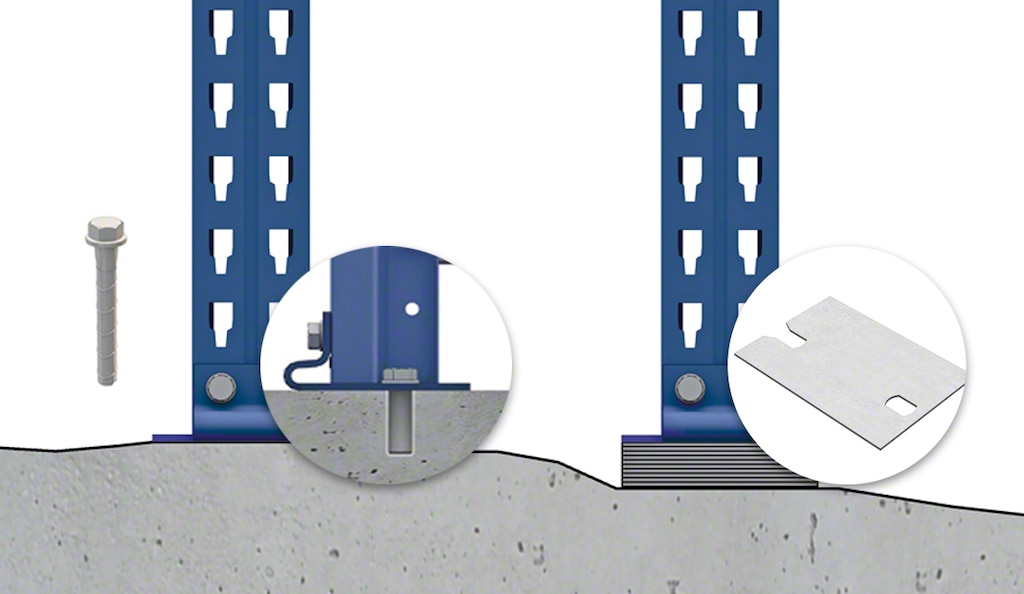

Shims

Metal components placed under profiles that stand on uneven flooring to ensure that the pallet rack structure maintains its center of gravity.

Locking device

The endplate that connects the post to the beam has a locking device that prevents the beam from accidentally disengaging. As it is welded to the endplate itself, it’s impossible to remove the safety device, which reinforces the safety of the entire structure.

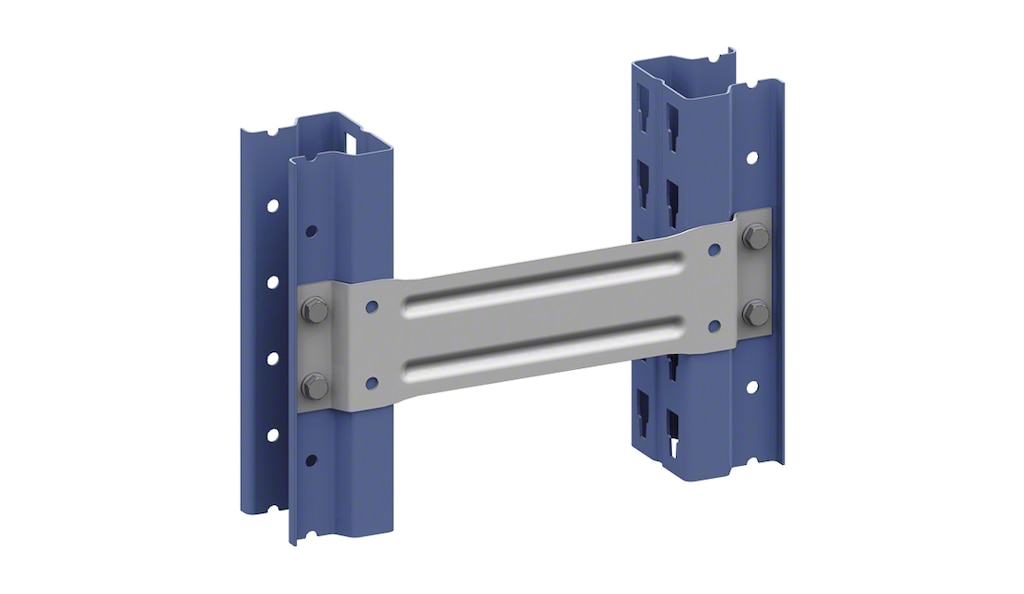

Row spacer

Steel component that joins two posts of different pallet rack modules.

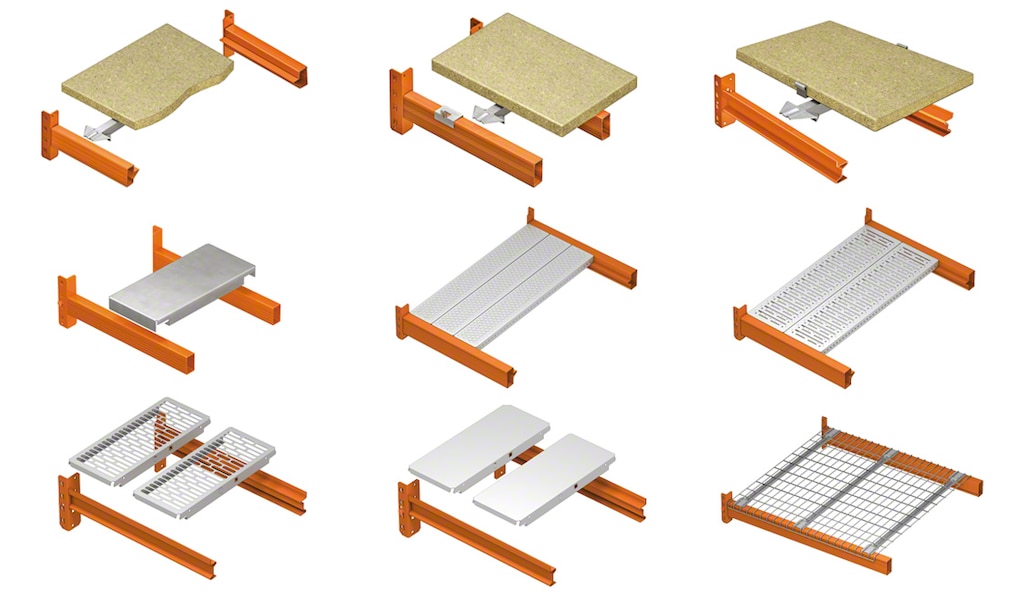

Types of shelving panels

When storing pallets, there are no shelves, per se, as the goods are directly supported by the beams. However, other types of unit loads are deposited on shelving panels. Various types of shelves can be installed in line with the types of goods to be stored:

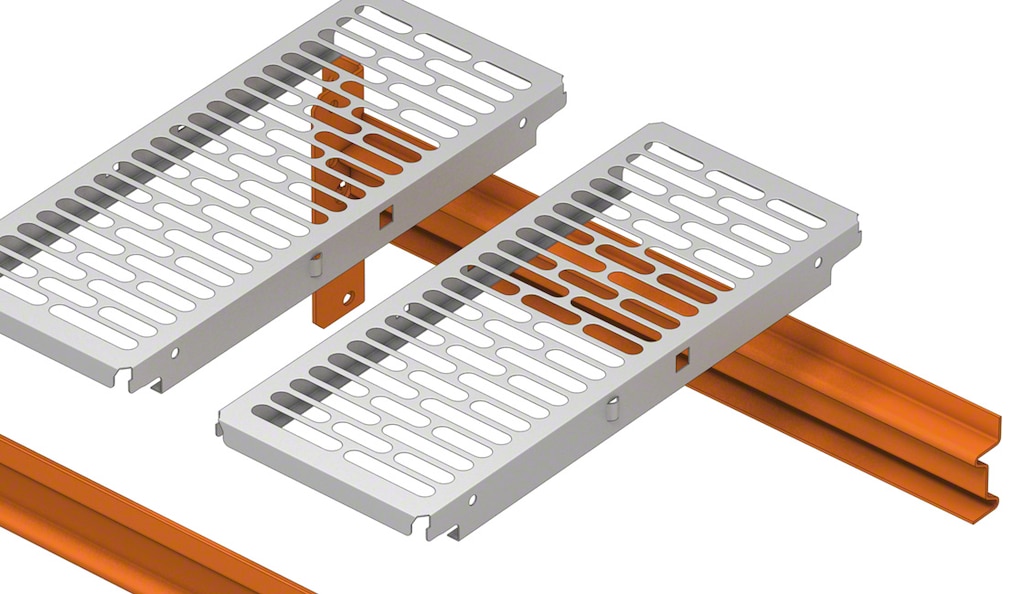

Galvanized shelving

Shelf panels fitted directly on the beams, without the need to incorporate an additional fastening element to the racking. They’re ideal for housing bulky goods due to their high load capacity.

Metal shelving

Fitted directly onto each level of the racking, these shelves usually serve for picking at various levels. These types of shelves are available in several versions (slotted, grooved, or perforated) according to the air circulation needs of the product stored.

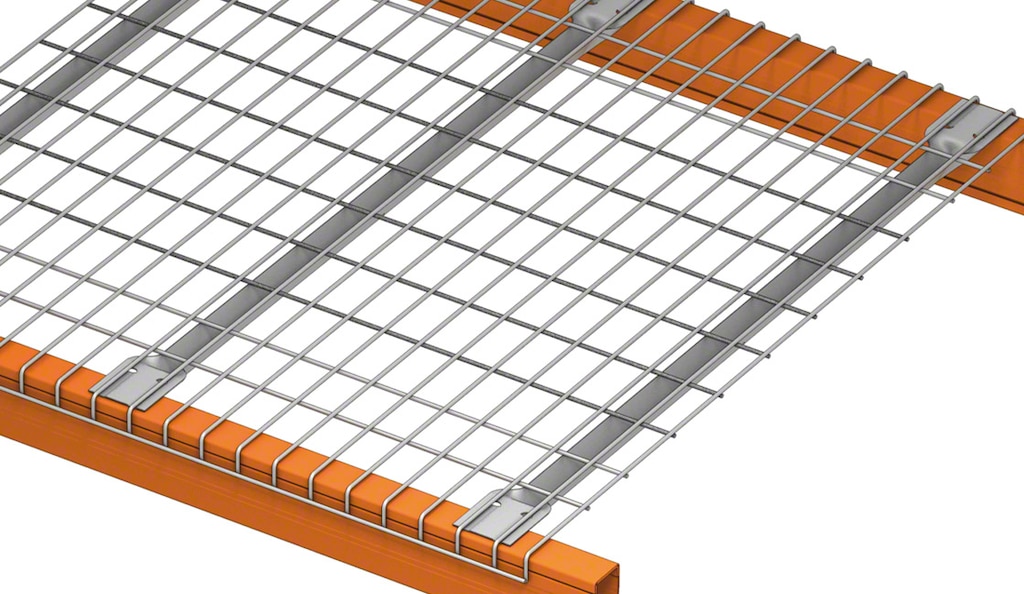

Wire mesh shelving

Panels formed by electro-welded wire mesh that, supported on the crossbars, reinforce the stiffness of the structure. These shelves guarantee that the automatic sprinklers work efficiently by allowing water to circulate through the shelving.

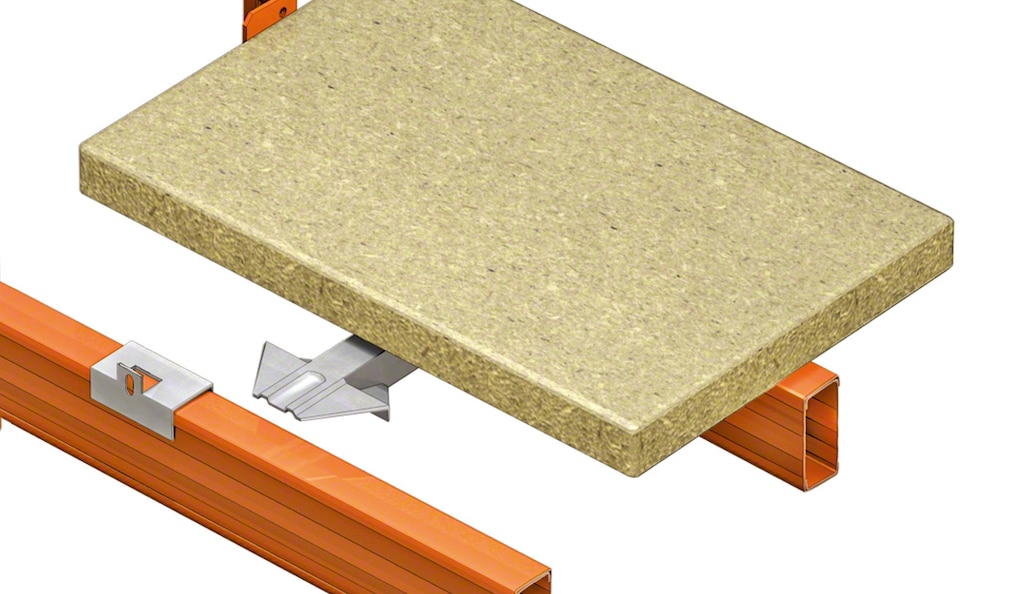

Chipboard shelving

Chipboard shelves can store all kinds of loads. Based on the size and weight of the goods, crossbars can be added to increase the structure’s load capacity.

Pallet rack safety accessories

Pallet rack parts also include a number of accessories designed to enhance the safety of the goods, the racking structure, and, of course, the operator. These are the most common safety accessories:

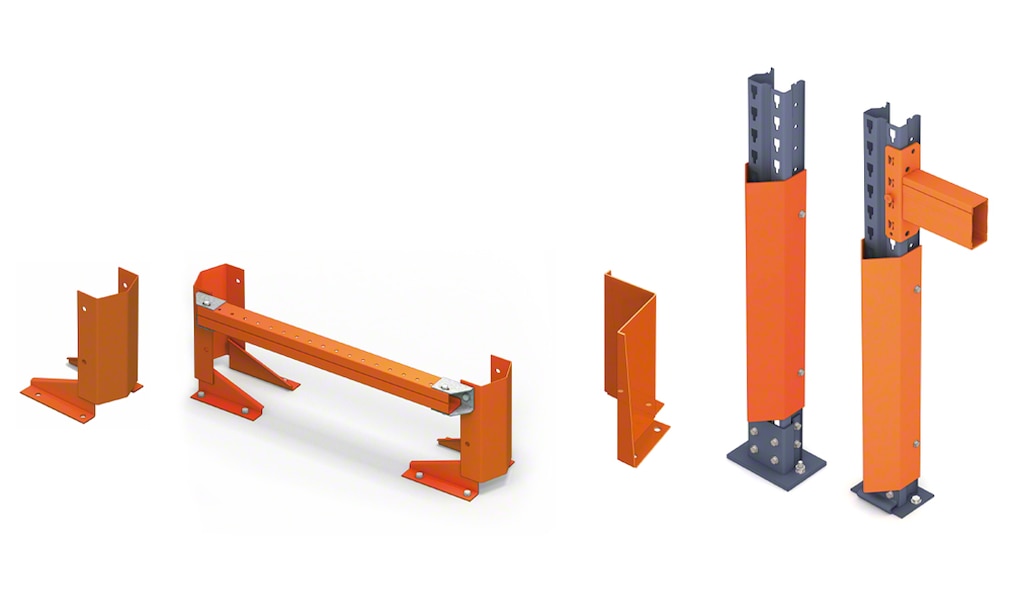

Protectors

Pallet racks incorporate protectors to avoid structural damage from accidental blows. These safety elements comprise:

- End aisle protector: fitted to the ends of the frames, where impacts are more probable.

- Post and frame protectors: used to prevent structural damage for pallet racks managed with forklifts.

- Corner protectors: made from folded metal sheets that guard the outer posts when post protectors can’t be directly attached.

- Post reinforcers: useful when it is necessary to protect the post at the base and also at a certain height.

Fall protection netting

Safety element installed on the back of the racking to prevent the accidental fall of goods.

Adapters for irregular loads

Pallet racks feature accessories for tailoring the storage structure to any kind of irregular load. These are the most relevant:

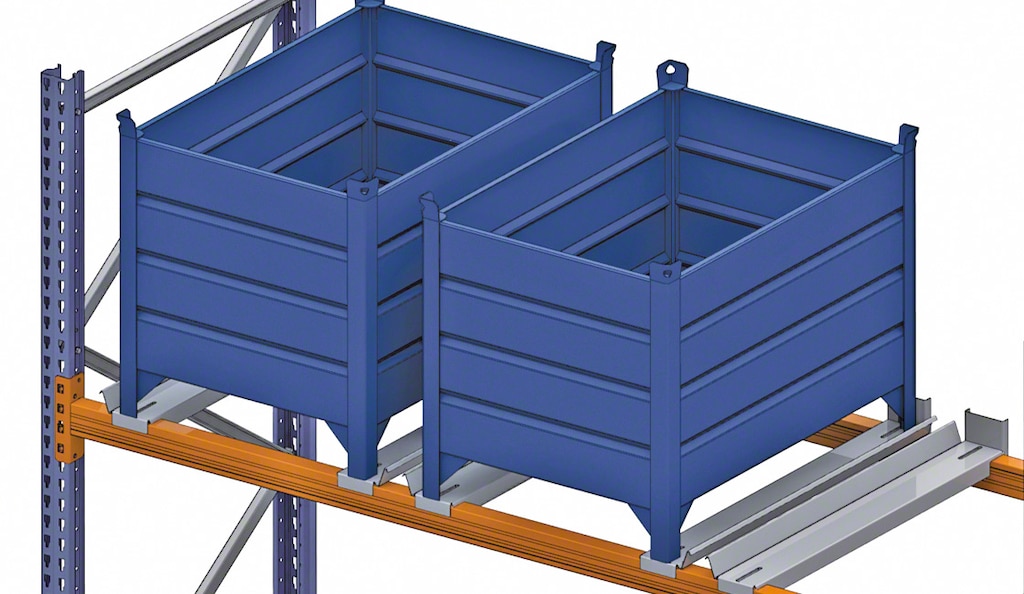

Container support

Metal part similar to a crossbar that sits perpendicularly on the beams when storing containers. To ensure that the load remains in place, two supports per container are used, one on the left and the other to the right of the unit load.

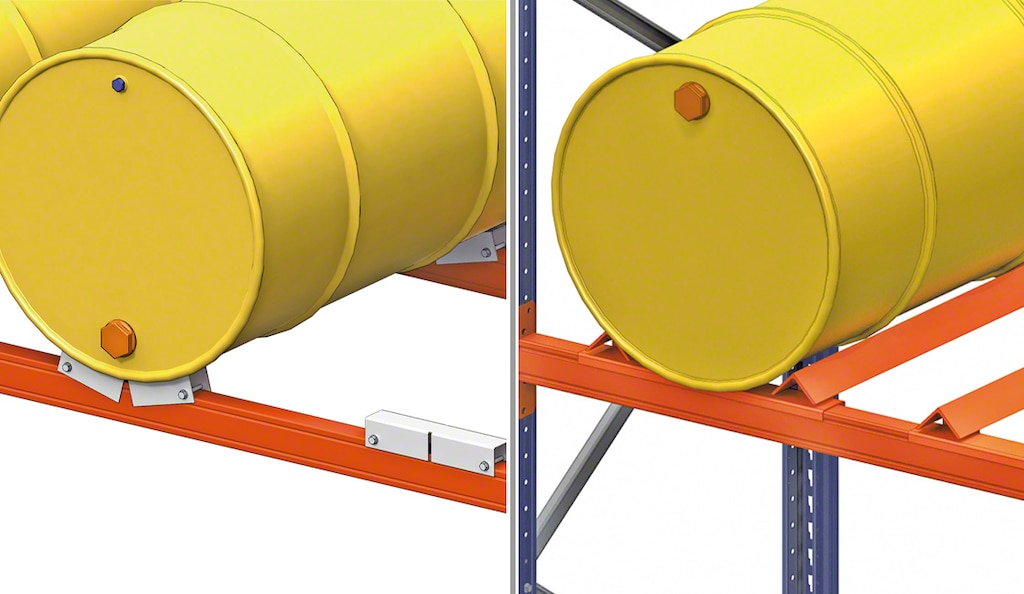

Drum/coil bed

Component that makes it possible to store drums and coils. It can consist of two rollers on which the drums turn, enabling liquid to be extracted from them. Alternatively, it can comprise a 2" V-shaped part that provides the support required to hold the load in place.

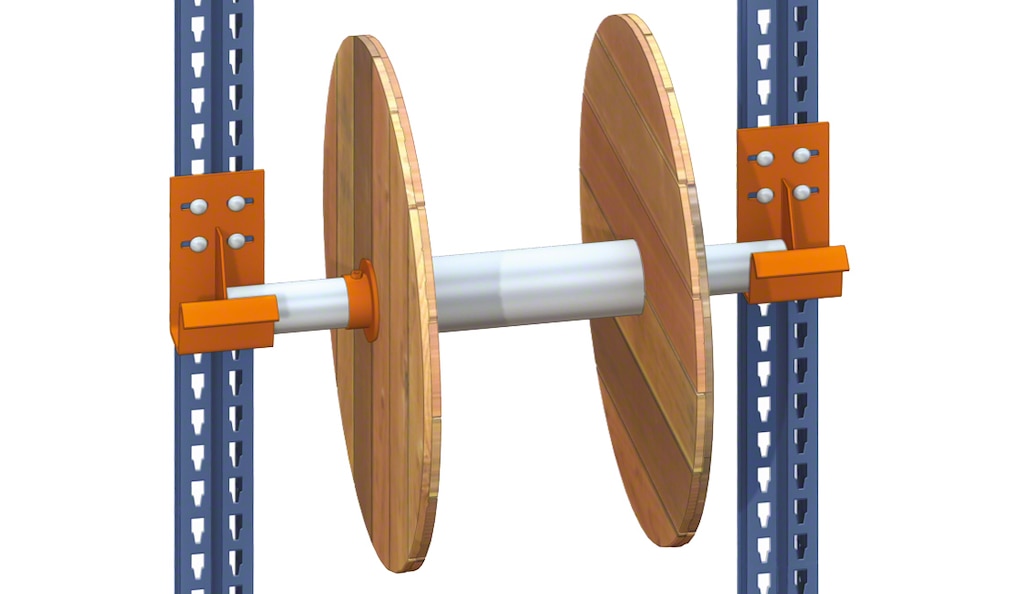

Drum cradle

Accessory used to store reels or other cylindrical elements. This part comes in different configurations, depending on the characteristics of the goods, the size of the load, or the function of the rack in the facility.

Signage accessories

Pallet rack parts also include elements that don’t exactly form part of the structure but that improve safety in the warehouse and make it easier for users to identify the goods. These are the most standard:

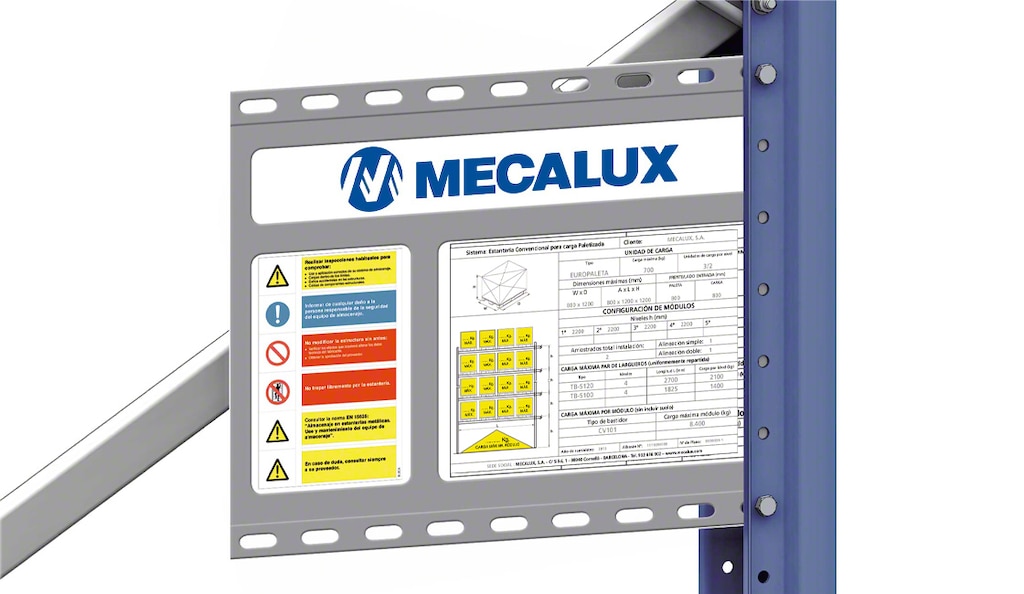

Safe load warning notice

Rectangular PVC accessory containing all the technical characteristics pertaining to the pallet rack. It is affixed to the ends of the racking so that it is visible to operators, technicians, and warehouse pickers.

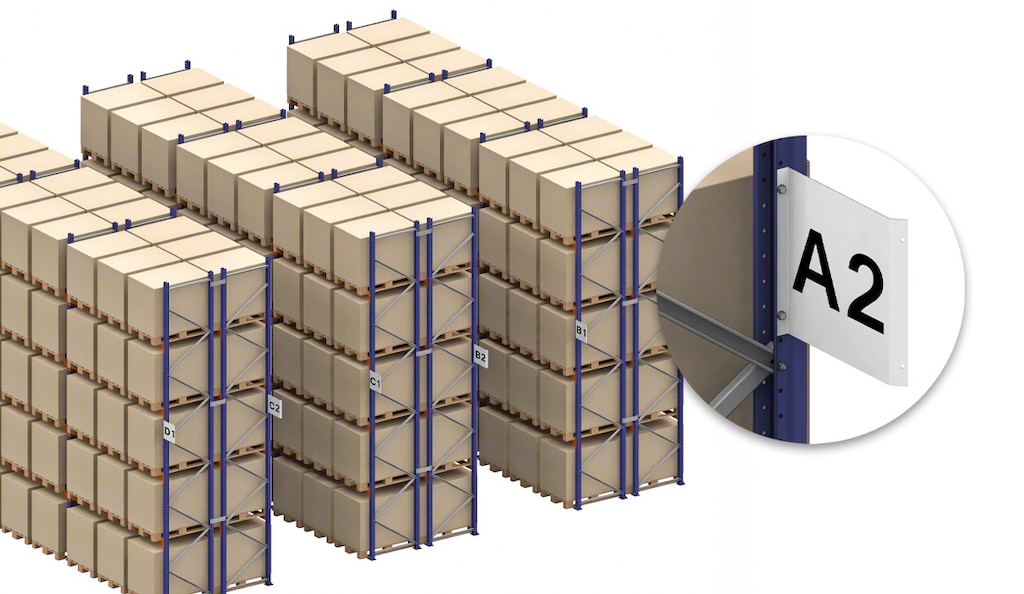

Aisle signs

Rectangular markers placed on the ends of the racks (at the beginning and end of every aisle). They display an internal company ID code. This sign makes it easy for operators to recognize which pallet rack module is in that aisle and what type of load is housed there.

Sign holder

Accessory incorporated on the post or beam to facilitate identification of the goods. It can be adhered to the post directly or with an ID card holder.

Quality and safety for every part of a pallet rack

The set of parts that make up a pallet rack ensure their stability, stiffness, and load capacity. Likewise, these storage solutions feature a wide variety of elements that adapt the racks to all type of goods and unit loads.

In fact, pallet rack parts such as bracing and crossbars increase the facility’s load capacity. Moreover, with the extensive range of shelving and beams available, these solutions can be customized to meet the needs of any customer. Want to know more about Interlake Mecalux’s pallet racking systems? Don’t hesitate to contact us. One of our expert consultants will work with you to come up with the best type of pallet racks for your warehouse.