5 companies with automated warehouses: examples and benefits

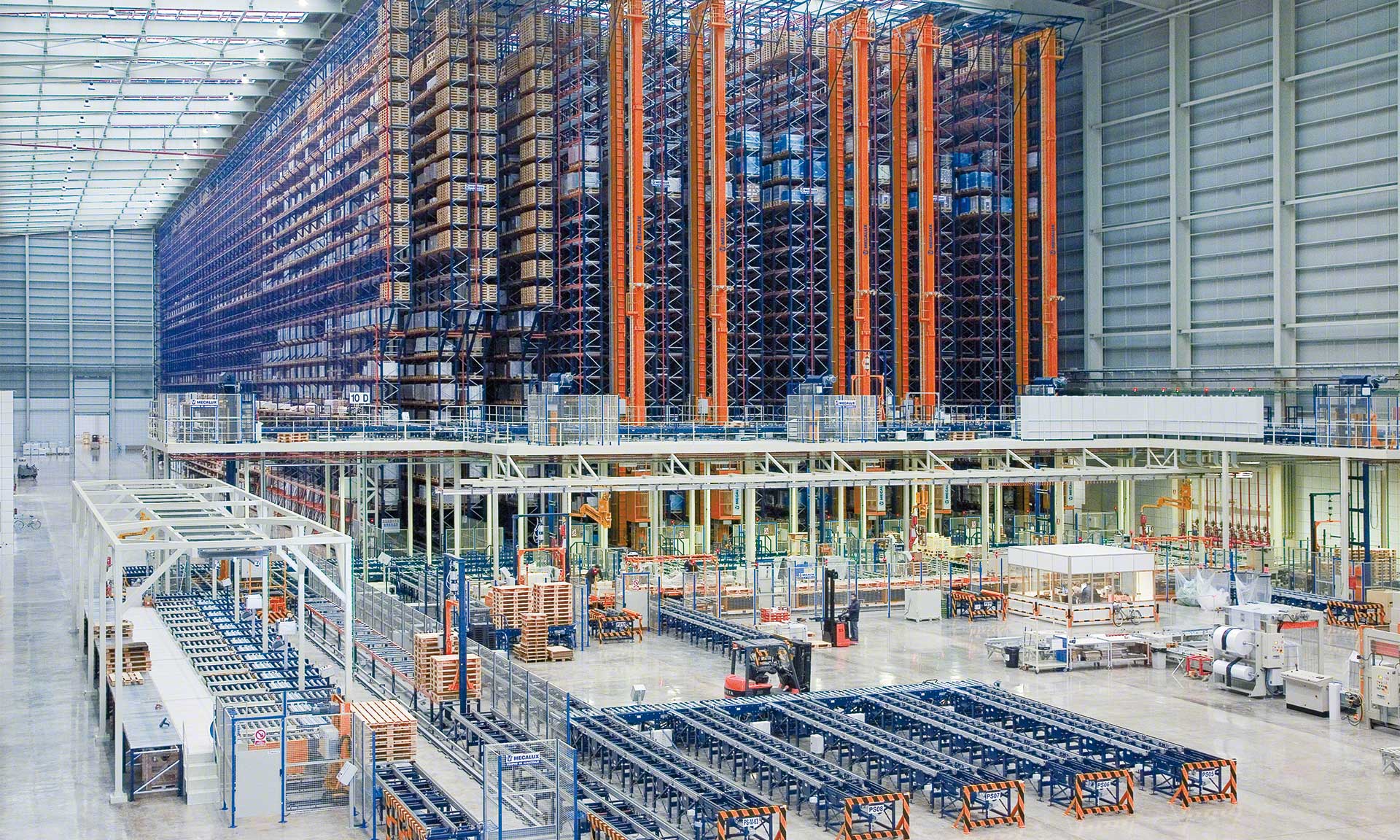

More and more companies are implementing automated warehouses to enhance the efficiency and accuracy of their logistics operations. In an automated warehouse, all transportation, storage, and goods management processes are fully automated.

Automated warehouses can be found in a wide variety of industries. They offer benefits such as reduced errors, optimized space, and faster processes. Below, you’ll find 5 examples of companies that have installed automated warehouses to boost their supply chain throughput.

Company 1: automated warehouse in Europe’s largest sugar processing plant

British Sugar, the leading sugar manufacturer in Great Britain and Ireland, optimized logistics operations in its sugar processing plant — the most extensive in Europe — with an automated warehouse for pallets. Overseen by the Easy WMS warehouse management system, the facility is seamlessly connected to production line outputs by a pallet conveyor.

Located in Wissington (UK), British Sugar’s automated warehouse is equipped with the Mecalux Group’s Automated Pallet Shuttle system with stacker cranes. This automated storage and retrieval system (AS/RS) has enhanced speed and safety in the entry and exit of 3,000 pallets a day containing finished products. It enables the business to comfortably keep up with production rate increases and changes in demand.

“All movements of goods are automated, which really accelerates product inflows and outflows. Thanks to the automated operation of the stacker cranes, conveyors, and motorized shuttles, we’re able to complete the cycles required to serve our customers,” says Samuel Chapman, Purchasing Manager at British Sugar.

Michael Burton, Customer Supply Lead at British Sugar’s Wissington Factory, explains why the organization opted for new technologies: “Innovation is at the heart of everything we do and is fundamental to our factories of the future.” He also notes that automation has provided multiple benefits, “most notably the improvements in safety and health as a result of the reduction of forklift movements within the warehouse.”

Company 2: processing 500 order lines per hour with spare parts

Companies that implement automated warehouses seek efficiency and safety in inflows and outflows of palletized goods. But they also aim to expedite picking of small parts. A case in point is the Manitou Group, a company specializing in material handling, people-lifting, and earthmoving equipment. It installed the Mecalux Group’s Shuttle System and 2 high-performance pick stations in its logistics center in Ancenis, France. With Mecalux’s Easy WMS, the business closely monitors its 16,000 SKUs in stock.

This comprehensive solution has increased productivity and capacity in the same space. The Manitou Group can prepare 500 order lines an hour following the goods-to-person method. At the same time, it houses and manages 20,000 boxes in real time in just 6,028 ft².

“We’re extremely satisfied with the performance of the Mecalux Shuttle System. It’s ramped up our productivity in storing, picking, and shipping spare parts. Additionally, Easy WMS more than meets our expectations. It’s a very intuitive and user-friendly digital tool,” says Benoît Stanislas, Supply Chain Project Manager at Manitou Group.

In designing the AS/RS, Mecalux also took into account Manitou Group’s growth strategy. The automated solution, which consists of 2 aisles, is scalable. That is, the organization can add another aisle to handle a higher order fulfillment volume in the medium and long term.

Company 3: automating a manual facility without disrupting operations

Automated warehouses can be built from scratch. Alternatively — as in the case of IKEA Components — they can be implemented in a pre-existing facility. The company, which packages and distributes furniture parts and accessories, automated its warehouse in Malacky, Slovakia, with AS/RS trilateral stacker cranes and pallet conveyors without halting operations.

Frantisek Stora, Managing Director of IKEA Components Slovakia, says: “We had experience in warehouse automation but primarily in greenfield projects — started from scratch. With Mecalux’s help, we transformed an existing facility, leveraging the building structure and racks. The project was more challenging than others we’d done in the past, but now that it’s finished, I can confidently say that it’s been a complete success.”

Made up of 12 aisles, the automated warehouse streamlines the storage of finished products from the production lines. Moreover, it has a 99% order fill rate, attributed in part to the effectiveness of Mecalux’s Easy WMS. “With the warehouse management software, we can see our material flows and how much stock we have in the facility at any given time,” says Pavol Masarovič, Operations Manager at IKEA Components.

In conclusion, Masarovič highlights the advantages of transforming the facility: “Automation brings us flexibility, efficiency, and the storage capacity we need. Likewise, the automated warehouse gives us real-time inventory visibility.”

Company 4: automated warehouse in Europe’s most modern metal packaging plant

Blechwarenfabrik, a manufacturer of aluminum cans, installed 2 automated warehouses in its plant in Offheim, Germany. One houses raw materials, and the other, finished products. The two are linked by means of automated guided vehicles. This systematic connection between production and logistics operations enables the company to process 24,250 tons of steel annually, making over 100 million packaging units.

“We’ve automated goods management, from inbound flows to order shipping. In partnership with Mecalux, we’ve built the most modern metal packaging plant in Europe,” says Christoph Weber, Technical Manager at Blechwarenfabrik.

To effectively combine logistics and manufacturing operations, the company employs Easy WMS software. The Mecalux program connects with Infor, Blechwarenfabrik’s ERP system, and its manufacturing execution system (MES) to know which items are needed in production and organize their distribution. “The programs support each other. If we’re looking for information on products, Easy WMS gives us all the details, including the available quantities and exact locations,” says Uwe Wonsack, Operations Manager at Blechwarenfabrik.

With the automated solutions from Mecalux and management provided by Easy WMS, the company benefits from an interconnected supply chain. Consequently, it now maintains tight control over its processes and provides its customers with top-rate service. “When we opened the new plant in Offheim (Limburg), it was clear that our facility had to be automation-driven. With the technology of our partner Mecalux, our supply chain has taken a huge leap forward,” says Wonsack.

Company 5: boosting productivity by 20% with an automated warehouse

Automated warehouses are ideal for enhancing efficiency in facilities that work with frozen and/or refrigerated products. Copacol (Cooperativa Agroindustrial Consolata – Consolata Agribusiness Cooperative) centralized its logistics operations in a fully automated distribution center (DC) in the Brazilian town of Corbélia.

The company set up 2 automated warehouses that run at different temperatures. The first is a rack-supported building that houses frozen products (made primarily from chicken and fish). Its 4 aisles, which operate at -13 °F, hold 13,780 tons of chicken and 1,875 tons of fish. The other automated warehouse stores refrigerated products. It has a single aisle run at 39.2 °F and capacity for 1,430 tons of chicken.

“We have a very modern DC. It’s equipped with stacker cranes that perform the storage tasks autonomously. The speed of product inflows and outflows is much faster than it would be with forklifts. Plus, as the stacker cranes do all the work, we’ve gained in accuracy and eliminated errors,” says Itamar Ferrari, Logistics Manager at Copacol.

With the automated warehouses and Mecalux’s Easy WMS — which ensures real-time product traceability — Copacol has raised its productivity by 20%. It now ships 1,020 tons of meat a day.

Automated warehouses for businesses in any sector

Automated warehouses offer efficiency and accuracy, optimizing inventory management and the supply chain. Therefore, they can benefit all types of products and companies.

Planning on automating your logistics facility? It’s best to seek advice from experts who can guide you in choosing the most suitable solution. At Interlake Mecalux, we have extensive experience implementing automated warehouses. Feel free to reach out. We’re here to support you in finding the right AS/RS for your supply chain.