Mecalux and KPMG drive warehouse digitalization in France

April 19, 2024Consulting firm KPMG will incorporate Mecalux’s warehouse management system in its technology services for clients in the French market.

Consulting firm KPMG will incorporate Mecalux’s warehouse management system in its technology services for clients in the French market.

Food and beverage multinational PepsiCo will install Mecalux’s Automated Pallet Shuttle system with transfer cars in its Veurne plant (Belgium).

The leading European consumer goods distributor will install a storage system with a capacity for nearly 50,000 pallets in its new facility in Donja Zdenčina (Croatia).

Sabarot, a French company specializing in dried legumes, cereals, and wild mushrooms, further enhances its logistics capabilities at its Chaspuzac center.

Interlake Mecalux will showcase its new line of AMR robots and its DOM software at Modex 2024, the premier event for logistics companies worldwide. The Interlake Mecalux stand will feature an immersive experience in a virtual warehouse via a 3D vision system.

Logistics provider Sidler Transporte & Logistik will digitalize 3 warehouses in Switzerland with Mecalux’s Easy WMS warehouse management system.

Number 1 Logistics Group has opened a warehouse equipped with Mecalux seismic racking in response to the food sector’s growing demand.

The Mecalux Group launches issue No. 31 of Best Practices magazine, with reports on technological trends in logistics such as AI. It also features case studies of clients that have automated and digitalized the management of their facilities to increase productivity.

The company will install the Automated Pallet Shuttle system, pallet conveyors, selective pallet racks, and Easy WMS software.

The paper packaging company will install the Mecalux software in its facility to strictly monitor materials sent to production and finished goods.

The agricultural machinery manufacturer will equip its logistics center with a mini-load system, a high-performance pick station, and Easy WMS software from Mecalux.

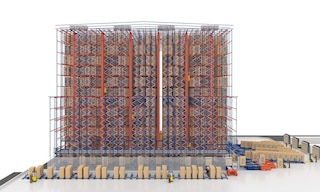

Eurofrigo, a logistics provider specializing in storing and handling frozen goods, will install a seismic-resistant automated warehouse in Vitulazio (Italy) managed by Easy WMS.

Issue No. 30 of Best Practices features a special report on the Mecalux Group’s new robotic picking solution. It also includes success stories from clients who have relied on automation and digitalization to optimize their logistics processes.

Mecalux and Siemens have joined forces to optimize order fulfillment with an automated picking solution driven by artificial intelligence. Mecalux’s system incorporates Siemens’ SIMATIC Robot Pick AI technology, a pioneering vision software program built on deep learning algorithms.

The Polish manufacturer of laminate wood and vinyl flooring will be modernizing its supply chain with two AS/RS, conveyor systems and Mecalux management software.

The distributor of motorcycle gear and accessories will manage its facility with Easy WMS in the cloud.

Mecalux will install an AS/RS, Easy WMS software, and two pallet storage systems in the DC of Poland’s leading logistics provider for deep-frozen products.

The producer and distributor of dairy products and juices will install the automated Pallet Shuttle system and Easy WMS software in its Santo Domingo warehouse.

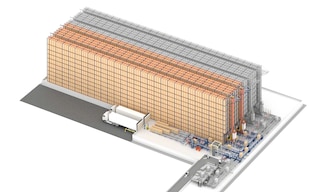

LD, a renowned Mexican logistics provider, will build an AS/RS to respond more swiftly to its customers’ needs.

Bardinet, a leading player in the global wine and liquor industry, will install an AS/RS for pallets in its logistics center.